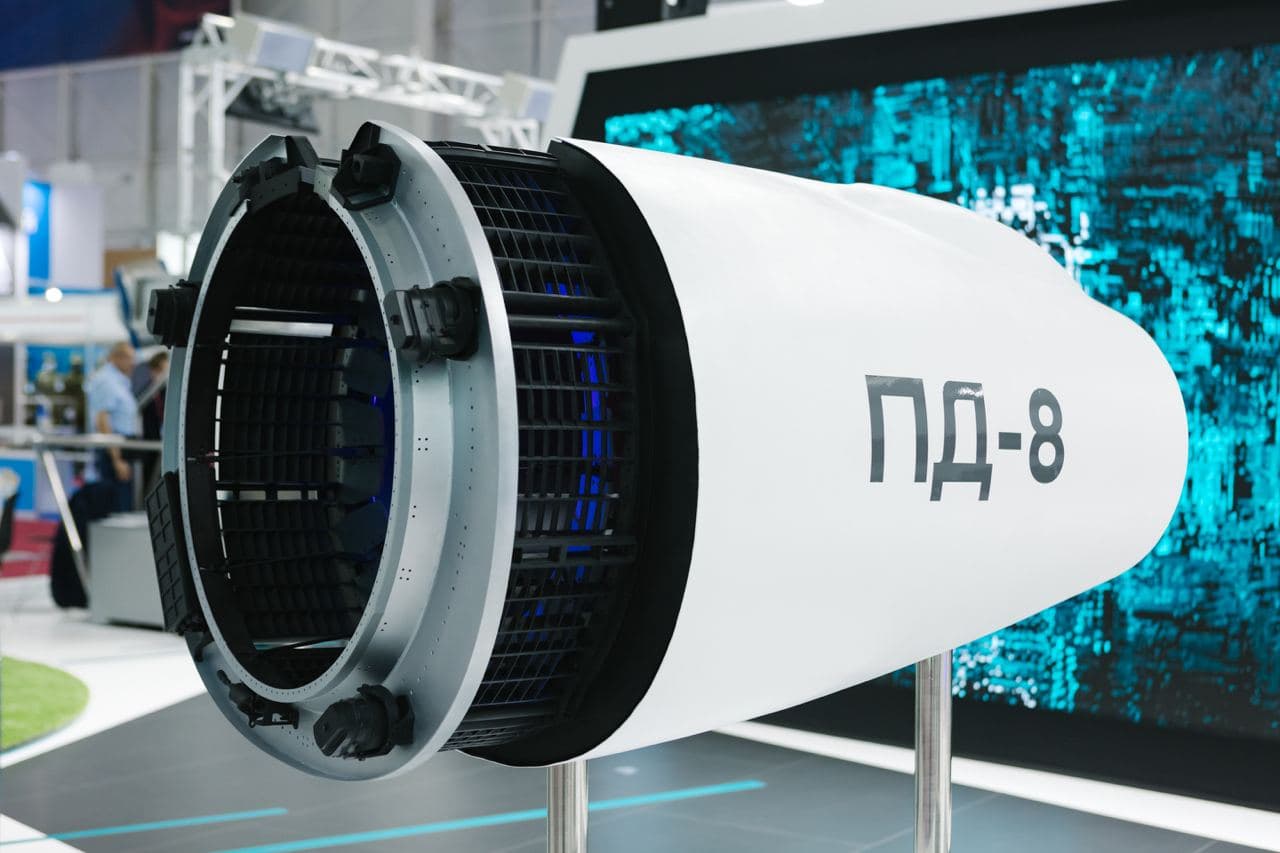

Parts of the newest domestic PD-8 aircraft engine for the Superjet SJ-100 and Be-200 are manufactured at UEC-Saturn using 3D printing methods with additive technologies. This approach reduces the weight of power plants while maintaining the strength of materials.

Deputy Chief Engineer of UEC-Saturn for Additive Technologies, Denis Fedoseev, noted that the company has introduced synthesized parts into the standard design of aircraft engines.

More than a dozen PD-8 parts are mass-produced using additive technologies. During the development phase, more than 200 synthesized parts were designed, and more than a thousand were manufactured.

The United Engine Corporation (UEC) showed a video of the process of creating a part for the PD-8 aircraft engine using selective laser melting.

This refers to the oil sump housing, an important element of the unit's oil system. The manufacturing process includes mandatory optical control and X-ray control of the product, which confirm the quality of the part and its compliance with the specified parameters.

PD-8 engines are designed for the SJ-100 aircraft and the Be-200 amphibious aircraft. In the second case, testing will begin in mid- or late 2026.

Earlier, www1.ru reported that China will not take off without the PD-35: it has no other engine for the wide-body C-929.

Read more on the topic:

Millions were given for old aircraft engines of military aircraft AL-21 and AI-25 TL

A millionth ingot of titanium for the construction of MS-21 and SJ-100 was smelted in Russia

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation