A coaxial propeller scheme is an advanced power plant architecture in which two or more propellers are placed on a common axis and rotate in opposite directions. This configuration not only eliminates undesirable aerodynamic effects, but also significantly increases the efficiency of the entire propulsion system.

How does the coaxial system work?

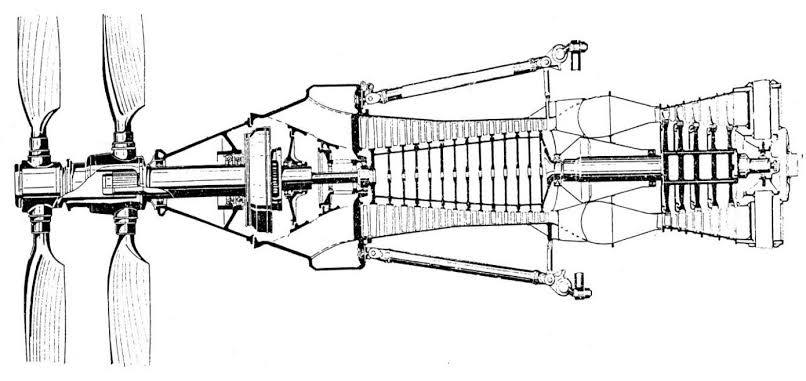

Structurally, the implementation of a coaxial scheme requires the use of a specialized gearbox capable of converting the unidirectional rotation of the engine shaft into the counter-rotation of two coaxial shafts. At the same time, the blades of the front and rear propellers have opposite geometric pitch, which provides a total thrust in one direction, despite the antiphase rotation.

Reactive torque compensation is a key advantage

One of the main challenges when using a single propeller is the reactive (or torsional) moment. According to Newton's third law, when torque is transmitted from the engine to the propeller, the engine itself experiences an equal and opposite effect. It tends to turn the aircraft around the longitudinal axis, especially at maximum power.

In a coaxial system, the moments created by each of the propellers are mutually balanced. As a result, the reactive torque is practically reduced to zero. This eliminates the need for additional aerodynamic or structural measures to parry the moment, such as asymmetric tail assembly or the use of differential aileron control.

Reducing the diameter of propellers is the path to high speeds

Another advantage of the coaxial scheme is the ability to reduce the diameter of each of the propellers while maintaining the overall thrust. A smaller diameter reduces the circumferential speed at the ends of the blades, which moves them away from the threshold of the wave crisis. This is especially important when reaching high cruising speeds, when local sections of the flow on the blades can transition into the supersonic region, causing shock waves, a sharp increase in drag and loss of efficiency.

Real example: Tu-95 and NK-12 engine

The most striking example of the practical application of the coaxial scheme remains the Tu-95 strategic long-range bomber, equipped with NK-12 turboprop engines. These engines, developed in the USSR in the 1950s, are still considered the most powerful serial turboprop installations in the world. Thanks to the AV-60N coaxial propellers with a diameter of about 5.6 meters, the Tu-95 is capable of developing a cruising speed comparable to the speed of some jet aircraft of that time - up to 830 km/h.

Experts note that it was the coaxial layout that made it possible to achieve this level of speed without switching to purely jet propulsion, while maintaining the fuel efficiency characteristic of turboprop engines.

Read more materials on the topic:

- Tomsk scientists have created a compact rotary engine for drones with a capacity of 36 hp

- Will Russia create a competitor to Boeing and Airbus?

- Russian Tu-95MS strategists conducted an 11-hour air operation in the Pacific Ocean

Now on home

Price for the steering power unit not specified

The university also has a VR station for practicing tractor maintenance skills

Retired Rear Admiral Kovalenko sentenced to 4.5 years in prison for embezzlement

The designer reproduced all the diagrams from memory from magazines of the past era

Since the beginning of the year, the messenger has restricted the operation of 7.2 million public pages

Neuwerk can break ice up to 1.5m thick, while Russian counterparts of the "Arktika" project can handle three-meter ice

The Belarusian company ALEVKURP has agreed with a foreign customer on new deliveries of equipment

Modules with two 7.62 mm PKT machine guns are located on automobile platforms

Design with planetary gear, solar panels, and enhanced stabilization will expand the capabilities of autonomous missions

Managing Director of Ilyushin: the aircraft is of interest to many countries

Articles

-

TNI Thinks Russian PAK DA and Chinese H-20 Pose a Threat to the American B-21 Bomber

15 Feb 2026

-

From Czech Heritage to Domestic Engine: How the L-410 Fleet is Transforming in the New Geopolitical Conditions

11 Feb 2026

-

The National Interest: Russia Seeks Buyers for Su-57, But with Mixed Success

11 Feb 2026

-

The National Interest: Russia's Main Strength Is a Small but Advanced Submarine Fleet

10 Feb 2026