Kazan Aviation Plant (KAZ, part of the United Aircraft Corporation of Rostec) is switching to continuous assembly of the Tu-214 aircraft fuselage. Instead of fixture technology, the company is introducing a conveyor-based production principle. "Perviy Technicheskiy" in its article explains why fixtures in aircraft production are a thing of the past.

Why Fixture Assembly Slowed Down Aircraft Production at KAZ

First, we need to understand the terminology. Fixture technology has remained the basis of aircraft construction in Russia for decades. The fuselage was assembled on stationary structures, where each operation was performed manually and sequentially.

This approach ensured accuracy but sharply reduced production rates, since one body could remain on the fixture for months. Any delay in one area blocked the work of the entire line. Reconfiguring equipment took weeks, so scaling up production with this scheme is almost impossible.

As a result, the plant produced a limited number of aircraft even with orders and significant funding.

How Continuous Assembly Works

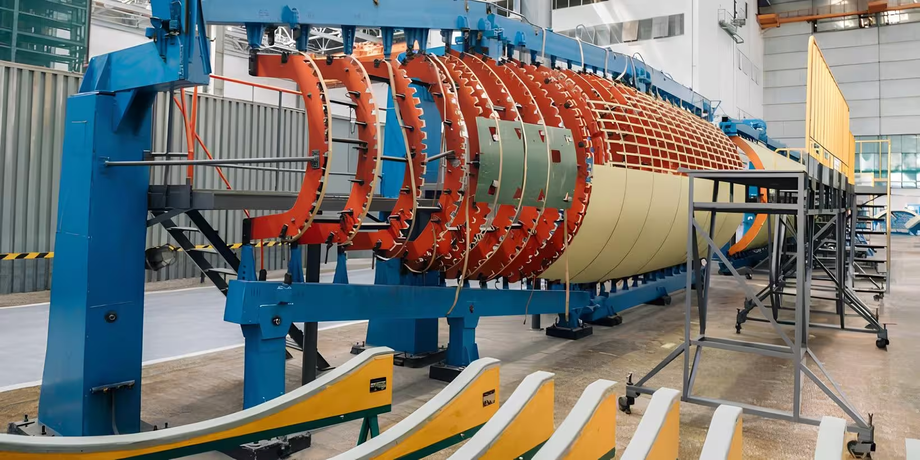

Continuous technology is based on the conveyor principle. The fuselage passes through several sections, where each team performs a strictly defined set of operations.

Each stage has uniform standards, digital control, and synchronized component deliveries. Work proceeds in parallel, without downtime or overlap. You can even draw an analogy with car production.

The new line will allow the Tu-214 fuselage to be assembled in 12 days. This is several times faster than the previous scheme. The project is being implemented with the support of the Agency for the Development of Professional Skills and the Center of Competencies in the Field of Labor Productivity.

What the Transition to Continuous Production Means for the Aviation Industry

Switching to continuous assembly instead of fixtures significantly changes the economics of production. The plant gets predictable deadlines, stable staffing, and reduced costs.

Increasing production to 20 "Tu" aircraft per year allows meeting the needs of airlines without constant supply disruptions.

Why This Is Called a Production Revolution

Abandoning fixtures means moving from one-off assembly to mass production. For Russian aviation, this is a key technological shift in recent decades.

The continuous scheme requires new competencies, digital management systems, and high supply discipline. If successfully implemented, the Kazan Aviation Plant will become a base platform for the large-scale production of domestic aircraft.

Read More on This Topic:

Now on home

Acceleration to "hundreds" is 10 seconds

The complex with a warhead of up to 3 kg, a speed of 200 km/h and capable of detecting targets at 4.5 km was presented at UMEX in the UAE

Students and schoolchildren are in danger

The company has produced over 12,000 rocket engines with a reliability of 99.9%

22 meters lifting height, 250 kg lifting capacity, and protection up to 10 kV - all in one solution

More than half of the products are intended for foreign customers

Police recorded massive attacks with phishing emails

The method is suitable for cleaning chernozems, loams, and sandy soils

The aerosol mixture penetrates shelters, and a volumetric explosion destroys them

The development is based on the approach - "physical model + AI"

Articles

-

Coaxial Propellers: How Counter-Rotation Increases Turboprop Engine Efficiency

25 Jan 2026

-

Kazan Aviation Plant Breaks Old System: Tu-214 to be Assembled Like Cars

25 Jan 2026

-

How Engineers and Technicians Are Paid Today in the Russian Aviation Industry: An Overview with Figures

24 Jan 2026

-

"The program was compiled by janitors": Honored pilot called the CPGA for a thousand aircraft absurd

24 Jan 2026