Lightweight heat-resistant alloys for a promising Russian aircraft engine surpass global counterparts. This was stated by the head of Bashkiria, Radiy Khabirov.

He specified that innovative materials are being developed at the Ufa Engine-Building Production Association (UMPO, part of the United Engine Corporation).

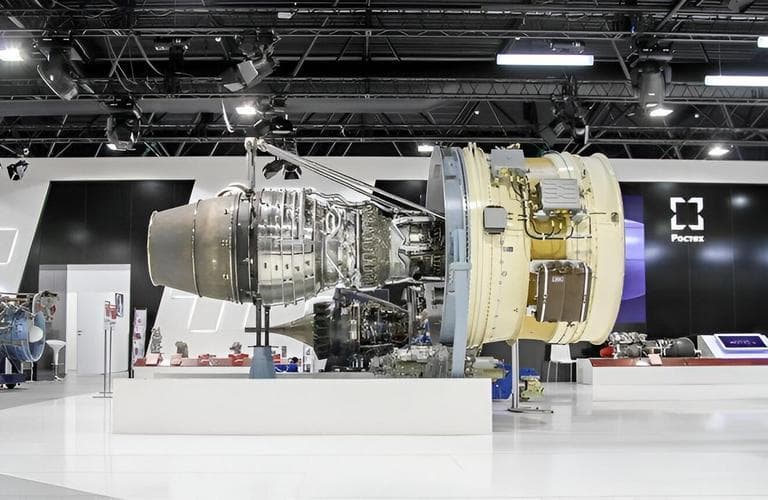

The company also mass-produces hollow blades for the PD-14 aircraft engine.

The lightweight heat-resistant alloys created here for the promising PD-35 engine even surpass global counterparts. The institute's technologies for Rosatom's gas centrifuges ensure the country's leadership in nuclear energy.

It should be noted that the PD-35has entered the second stage of testing. Domestic compressor and turbine parts are being tested on the unit. The United Engine Corporation (UEC) stated that they had performed more than 50 launches of the PD-35, and as a result, it was possible to achieve a thrust of more than 35 tons when reaching takeoff mode.

Former Deputy Minister of Civil Aviation Oleg Smirnov noted that additional moneywill be invested in the development of the PD-35 at the suggestion of the country's top officials. There is no aircraft for the power plant yet.

Earlier,www1.ru reported thatRussia is launching a new production of parts for the MC-21 and SJ-100.

Read more materials:

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation