The efficiency of a gas turbine engine directly depends on the temperature of the gas flow coming from the combustion chamber and rotating the turbine. The higher its temperature, the greater the work of gas expansion in the turbine and the higher the engine efficiency, the United Engine Corporation (UEC) reported.

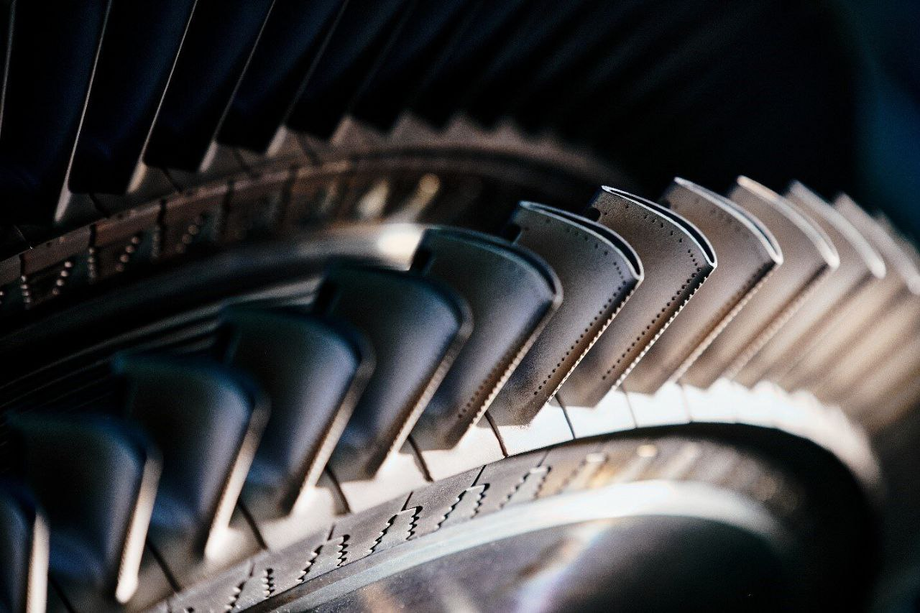

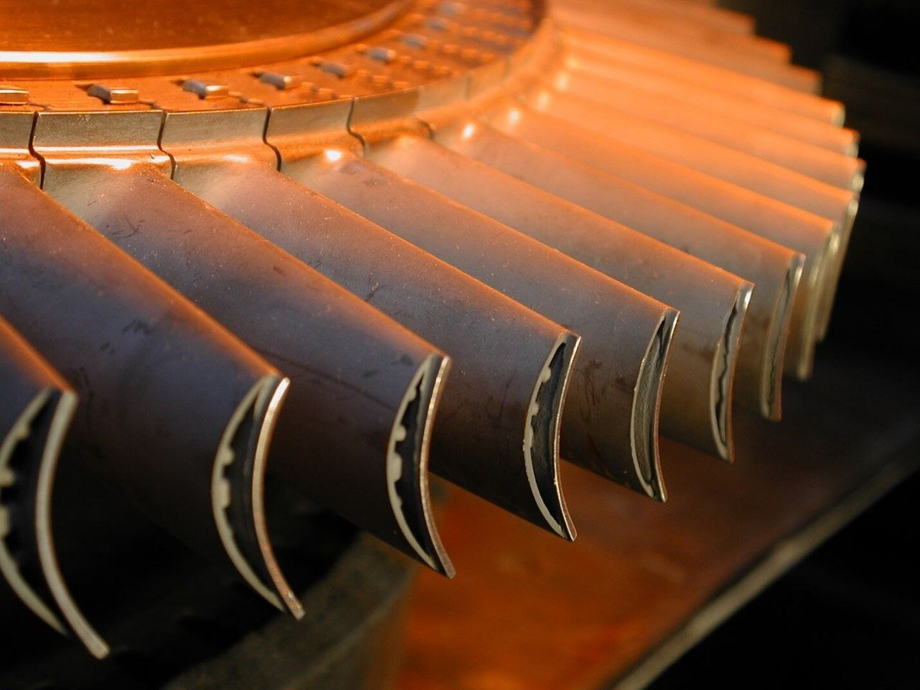

Turbine blades must withstand extreme temperatures for a long time, without losing strength and shape - above 2000 degrees Kelvin, which exceeds the melting point of the materials used to manufacture the blades.

Alloying elements are added to the heat-resistant metal alloys from which turbine blades are cast. These include tungsten, cobalt, chromium, molybdenum, rare metals rhenium, ruthenium and others. The number of such elements can reach 15.

UEC specialists also use thermal barrier and wear-resistant coatings, including ceramic ones, to protect the blades - they reduce the penetration of heat into the blade body and prevent gas corrosion of materials. However, these methods do not completely protect the blades from overheating, so a convective-film cooling system is used.

The coolant is air taken from behind the compressor stages and supplied through the cooling system to the turbine flow path. Entering the turbine blades through channels of various cross-sections, the air cools them by convection. Then, through holes of various configurations (perforation, slots), air is released onto the surface of the blade.

The temperature of this air is lower than the temperature of the gas flow acting on the turbine blades, so the air creates a barrier film on the surface that protects the blade from the hot gas flow.

Blades are among the most complex parts to design and manufacture in aircraft engines. At UEC enterprises, blades are produced using the most modern technologies. In the next issue, we will talk about one of these technologies - the cultivation of single-crystal blades.

Earlier www1.ru reported that the SJ-100 aircraft flew with the PD-8 engines turned off at a huge altitude: the UAC revealed the meaning of the experiment.

Read more materials:

Why does Russia really need the Baikal, Osvei, and Ladoga aircraft: the answer from Rosaviatsiya

The specification of the Su-30SM for Belarus has been revealed: they said goodbye to French avionics

The manufacturer of the MC-21 and SJ-100 suffered a net loss of 24.1 billion rubles last year