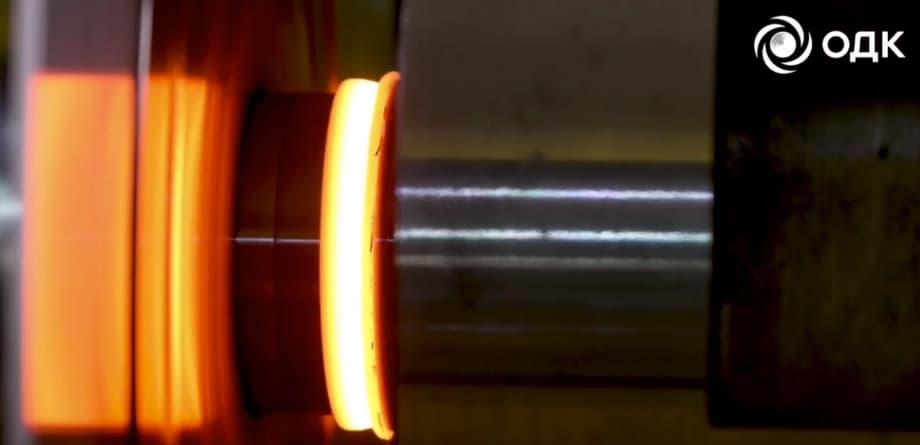

The United Engine Corporation (UEC) in its Telegram channel has for the first time shown the process of rotary friction welding. Heating is carried out in a thin surface layer of materials.

The high temperature required for welding is generated by the friction of surfaces under the action of rotation of one of the parts and simultaneous compression force.

The footage shows how the most plastic parts of the metal being processed are squeezed out of the joint of the parts during rotation. The moment of welding occurs after the rotation stops, when an additional compression force is applied to the part.

The technology allows welding dissimilar materials, including those that cannot be joined by traditional fusion welding.

The method of rotary and linear friction welding are critical technologies in modern engine building. Friction welding technologies reduce the weight and increase the service life of aircraft engines without reducing the strength of welded joints.

Earlier www1.ru reported that new Russian flying wing aircraft will be 20% more economical than traditional airliners.

Read more materials:

New Russian Tango aircraft to enter mass production in 2026

UEC handed over the second AL-41ST-25 industrial engine for trial operation

The latest MS-21-300 aircraft consumes half the kerosene of the Tu-154M

Now on home

Lukashenko's Chief of Staff: Settlements in digital currencies between countries will negate sanctions

Aircraft No. 64536 Climbed to an Altitude of 10,100 m During Tests

Yaroslavl SY owes 14.4 million, the court opened insolvency proceedings

Ministry of Defense: The protection was developed against strike UAVs and shaped-charge projectiles

The defense system also includes Verba MANPADS and new radar stations

Supply conditions are interpreted differently, auditors say

Airlines await security guarantees for flights in the conflict zone

Lieutenant General Kazmin: Neural networks increase the effectiveness of checks against the fingerprint database

Belgian authorities stated after the tanker's arrest that their country had "returned after years of decline"

Unresolved legal issues were called a major problem for the launch of drone delivery

Andrey Patrakov: tickets for LMS-901 will be "golden", subsidies are indispensable

Space station flights will be visible in the evening sky