The new MC-21 aircraft is close to completing certification tests. One of the key elements of the aircraft is the import-substitutedcomposite "black" wing, assembled in Ulyanovsk at the facilities of "AeroComposit". A retired special aviation pilot, author of the "First things first, airplanes" channel, explained the advantages of the design, as well as the direct impact of materials on the aerodynamic characteristics of the machine.

All modern aviation "stands" on composites

The retired pilot noted that he had seen aircraft of all generations - from heavy transport aircraft to combat vehicles.

And I must say: the "black wing" of the MC-21 is really a step forward. When you see it live, you understand that Russia has learned to do what all modern aviation is based on - composites.

Light as a feather, but stronger than metal

The main advantage of carbon fiber is its weight. They are many times lighter than metal, but at the same time withstand enormous loads. For an airliner, this means one thing - less weight = longer flight and less kerosene. At altitude,every hundred kilograms matters, and in the MC-21, composites make up more than 30% of the structure.

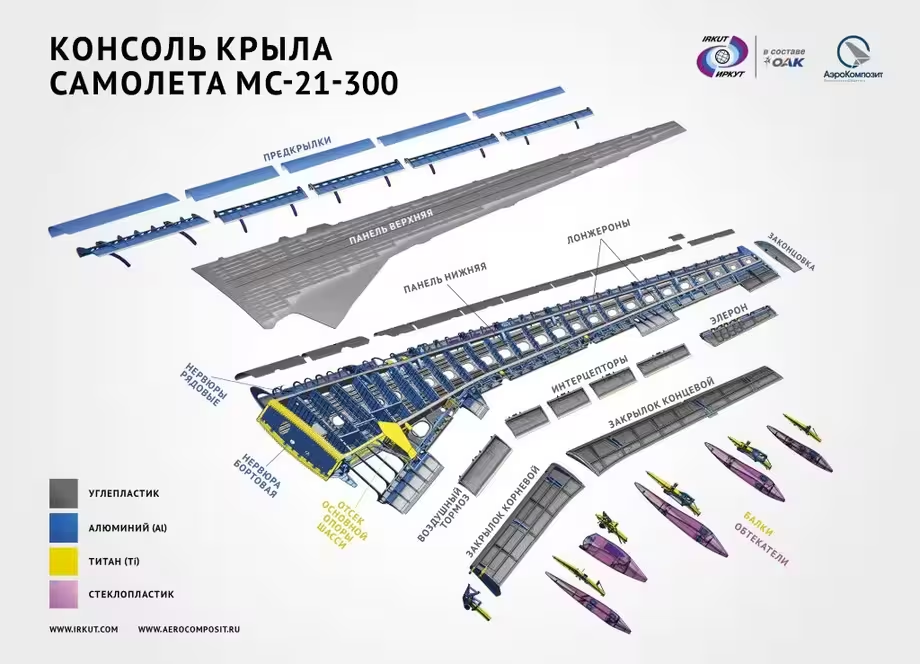

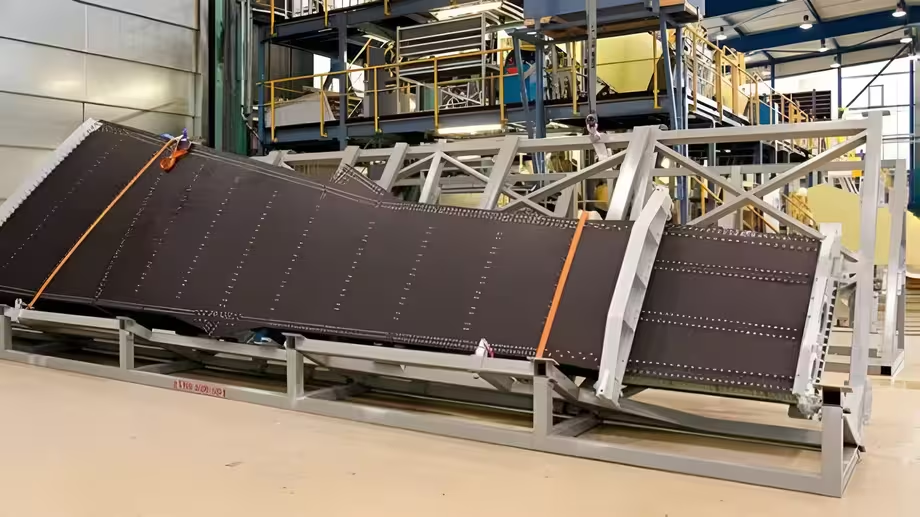

The "black" wing is not just a skin, but a solid power structure, where each carbon fiber tape is laid out with millimeter precision.

The result is an elastic, durable and at the same time "smart" wing that dampens vibrations and provides excellent handling.

How Russia overtook the whole world

The technology - VaRTM - is worth mentioning separately. Unlike American prepregs, it is cheaper and allows you to manufacture large panels without autoclaves. That is why even Japan Business Press called the Russian method the most economical in the world.

The "black wing" is not just a beautiful metaphor. This is a symbol of a new school of Russian aircraft construction. And as a person who has flown thousands of hours, I will say: if the plane is light, strong and manageable, then the engineers did everything right.

Increasing volumes

In 2025, the volume of composite materials produced by Rosatom for the aviation industrydoubled - up to 385 tons, said Alexander Tyunin, General Director of the Composite Division of the corporation.

The composite allows you to work for 100 years or more,without being exposed to water. Thanks to new materials, significant costs for the operational maintenance of composite vessels are reduced.

Earlierwww1.ru reported that the legendary Tu-134 will receive an unexpected purpose in the Moscow region.

Read more materials:

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation