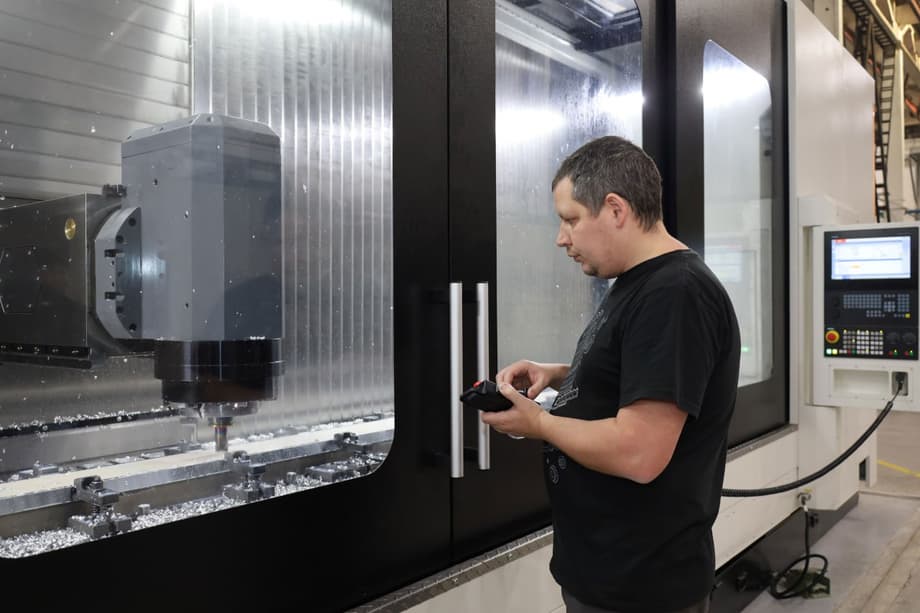

Two modern high-performance milling centers have been put into operation in workshop 221 of the Irkutsk Aviation Plant. In December, the commissioning phase was completed on the machines, geometry was checked, and test parts were manufactured.

The company's press service noted that the new three-coordinate machines were eagerly awaited in the division, as workshop 221 is very busy.

This equipment, designed for processing parts made of aluminum alloys, will be used to manufacture ribs, spars, beams, and other large components of the aircraft. The milling centers performed excellently during testing and were transferred to production at the end of last week.

The CNC system installed on the new machines is familiar to the employees of workshop 221, so there should be no problems with mastering the new equipment and its further operation. The first combat parts are planned to be manufactured on it in early January.

As a reminder, the Irkutsk Aviation Plant is part of PJSC "Yakovlev" of Rostec and produces MC-21-310 medium-range aircraft. Recently, the company also completedthe reconstruction of the main step-down substation, which will provide for all the needs of production.

Read more materials on the topic:

Now on home

Previously, drawings resembling Geely Monjaro appeared online, sparking rumors of cooperation

Journalist Alexey Kostylev faces up to 10 years in prison

A corresponding bill has been submitted to the State Duma

The products of the Samara plant are intended, among other things, for shipbuilding and mechanical engineering

Direct laser deposition and selective laser sintering were used in the production

"Buk-M3", S-300, "Tor-2", and "Pantsir" systems are capable of engaging this long-range cruise missile

The devices were manufactured by the Institute of Physical and Technical Problems

The enzyme system in the composition dissolves soft plaque and destroys bacteria

In terms of this indicator, the country is second only to Iraq, Iran and Saudi Arabia

The increase in prices for spare parts is explained by inflation, logistics and the aging of the car fleet

Fake messages were distributed from an unreliable address