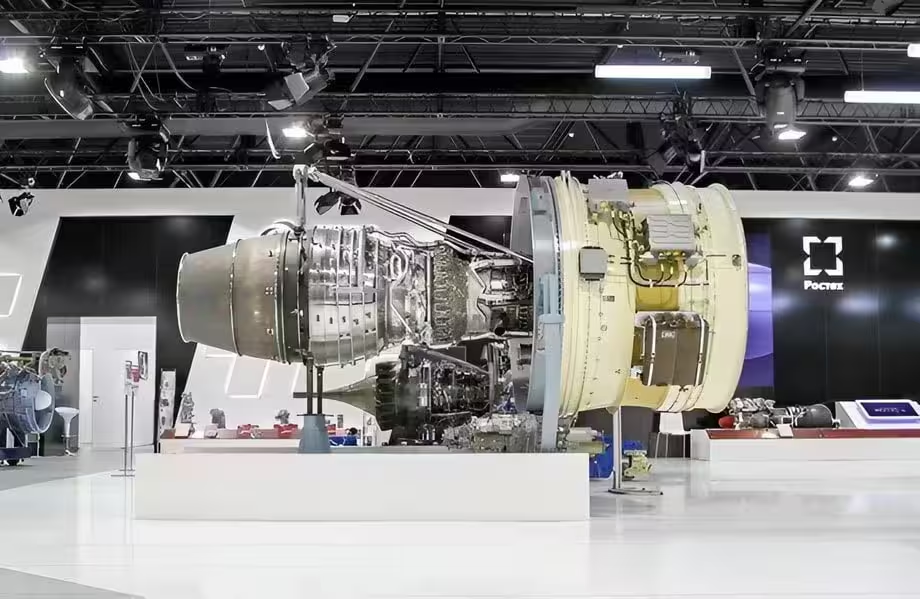

The Additive Technology Center of the United Engine Corporation (UEC, part of Rostec) has completed a large-scale modernization of production facilities. The updated infrastructure has significantly increased the production rate of critical components for promising PD-8, PD-14, and PD-35 aircraft engines.

A key factor in the growth of productivity was the widespread introduction of 3D printing technologies. Thanks to additive manufacturing, UEC engineers have reduced the manufacturing cycles of complex parts by dozens of times. For example, for the housings of fuel nozzles and sector nodes of the PD-35 engine, the production time was reduced from 4-6 months to just 24 days.

New 3D printing capabilities not only speed up production, but also pave the way for the implementation of fundamentally new design solutions - including geometrically complex parts that were previously impossible to manufacture using traditional methods. This increases the efficiency of engines and accelerates their refinement at all stages of the life cycle.

Read more on the topic:

Now on home

Anatoly Matviychuk: Bombers complement the nuclear triad and operate remotely

The Ministry of Defense was pleased with the work of high-payload UAVs

The Deputy Prime Minister of the Russian Federation emphasized the priority of the turboprop airliner's reliability over delivery times

Combat vehicle shot down 25 drones in a single sortie

Technology has been successfully tested

The project will be implemented at the plant in Nizhny Novgorod, where Skoda and Volkswagen were previously produced

Business Insider: New missiles have turned the aircraft into a dangerous adversary

The crew conducted aerodynamic and air pressure receiver tests at altitude

Starting price of the station at auction is 4 billion rubles

Mass production is scheduled to start this year at the gigafactory in Krasnaya Pakhra

No contractor was found for the development of the project for 2.37 billion rubles