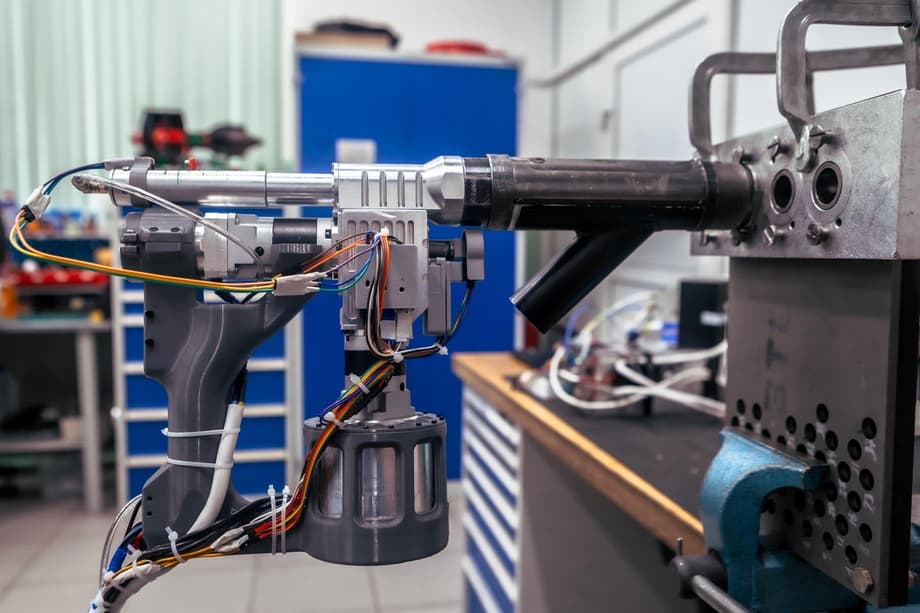

The Design and Technology Bureau of IrNITU presented the Irkutsk Aviation Plant (IAZ) with a sample of an electric drilling machine with automatic feed. Engineers designed and created a working prototype of the tool, intended for drilling holes up to 12 mm in diameter.

The tool is designed for drilling multi-layer aircraft parts (composite-steel-titanium-aluminum) and allows you to set individual processing modes for each layer.

Engineers have developed the mechanical part of the device, installed control, automation and coolant supply systems. The tool will be finalized to meet the needs of the aircraft factory.

The machine is planned to be used when joining the fuselage of the MC-21 and attaching the wing to the center section. In the future, the project envisages the creation of protective cases and software.

Read materials on the topic:

The newest MC-21 airliner has entered one of the key stages of serial assembly

PD-14 engine for MC-21 aircraft confirmed operation in icing conditions

Date announced for the start of flights of the newest MC-21 aircraft with the PD-14 engine