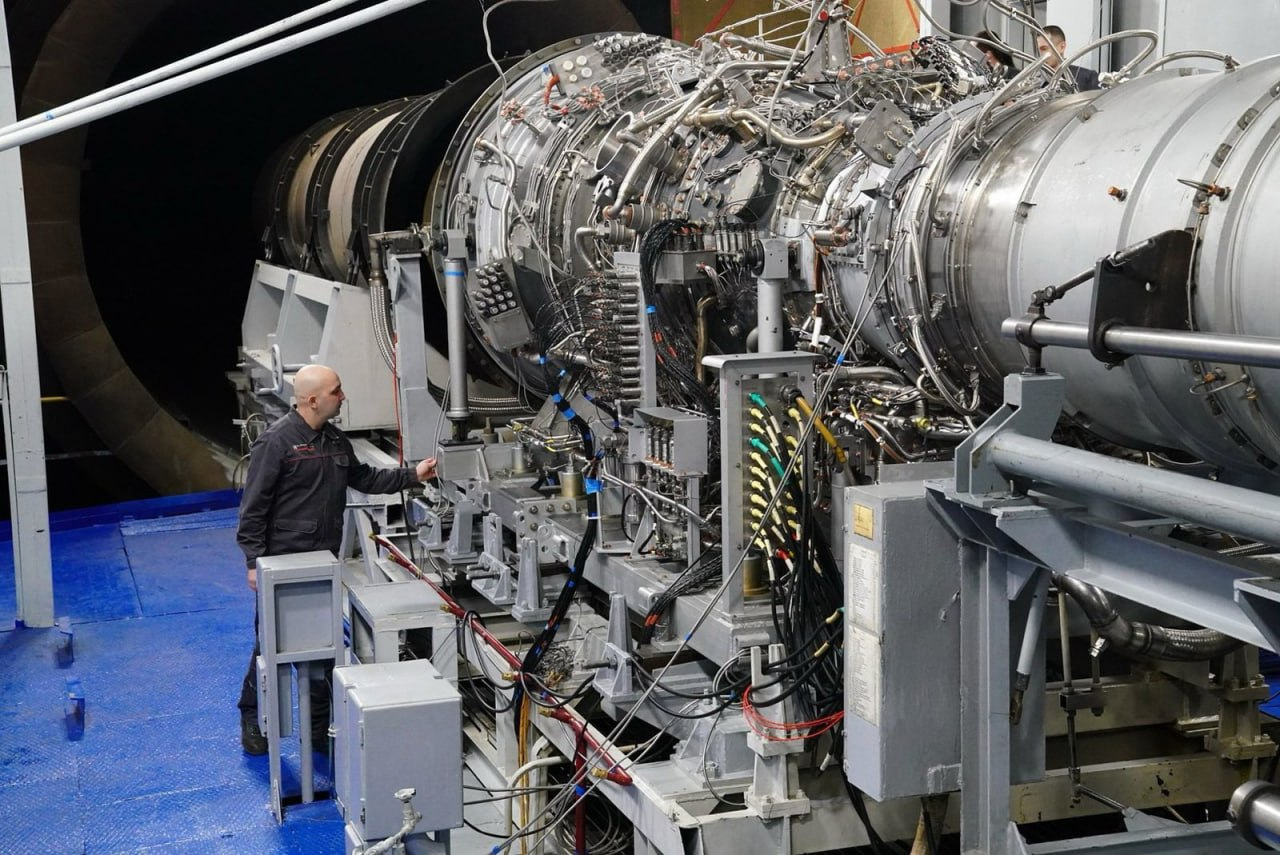

"ODK-Saturn" (part of PJSC "United Engine Corporation" of Rostec), was the first among UEC enterprises to introduce rotary welding for the serial production of gas turbine engine components. The new technology guarantees excellent quality of welded parts and significantly reduces the time spent on the operation.

Previously, electron beam welding was used in the manufacture of rotors at the enterprise. The use of the friction rotary welding method ensures 100% suitable parts for the welded joint and reduces the welding operation time by 10 times.

The press service of UEC emphasized that friction rotary welding is one of the key technologies in the modern aircraft engine industry. This method allows joining various materials, including those that are not amenable to traditional fusion welding.

The formation of a welded joint occurs due to rapid heating and compression of parts. The temperature increases in a thin surface layer as a result of friction, where one element rotates and the other remains static.

Earlier www1.ru reported that in order to increase the production rate of MS-21 aircraft at the Irkutsk Aviation Plant installation of four new machines has begun.

Read also materials:

- "Piracy and illegal seizure": technical inspection of the confiscated An-124 "Ruslan" began in Canada

- "4+" generation fighter-bombers Su-34NVO began to be equipped with modernized UMPC-PD

- Beyond the ordinary: how and why was the prototype of the fifth-generation Su-47 aircraft with a reverse-swept wing developed

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation

Articles

-

Russian An-124 "Ruslan" Stuck in Canada for 4 Years and Accrues Millions in Fines

26 Jan 2026

-

Coaxial Propellers: How Counter-Rotation Increases Turboprop Engine Efficiency

25 Jan 2026

-

Kazan Aviation Plant Breaks Old System: Tu-214 to be Assembled Like Cars

25 Jan 2026

-

How Engineers and Technicians Are Paid Today in the Russian Aviation Industry: An Overview with Figures

24 Jan 2026