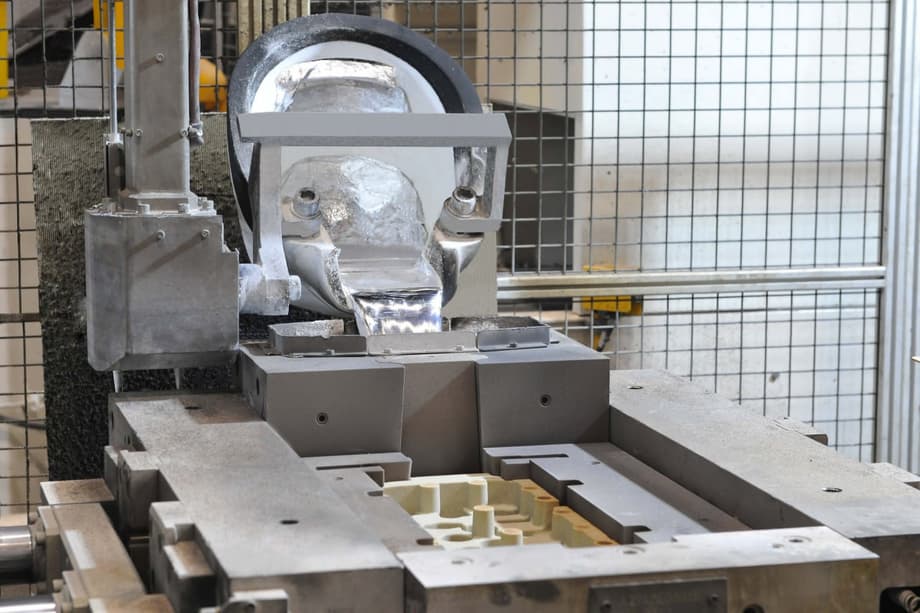

The company "Modern Transport Technologies" has introduced a new technology for casting cylinder heads (cylinder head) for Evotech engines at its plant in Nizhny Novgorod.

The main innovation is a change in the orientation of the casting. Now the mating plane is located in the lower part of the mold. This avoids defects (shrinkage cavities and porosity) in the upper part of the part.

The second innovation is the introduction of a mold water cooling system (a metal casting mold for creating castings) with seven independent circuits and automatic temperature control. This approach improves the metal crystallization process.

The operator installs the rods, then the system independently performs the pouring and extracts the castings, minimizing human intervention. Integrated error protection stops pouring if permissible temperatures are exceeded.

With the launch of the new foundry equipment, a semi-automatic belt machine for cutting off risers and two CNC machining centers were also installed. This improves the stability of the cylinder head geometry and eliminates manual finishing.

The updated technology will be used to produce castings for Evotech gasoline engines installed on the GAZelle NEXT and GAZelle Business models.

Earlier www1.ru reported that SUSU developed a method that increases the efficiency of electric motors.

Read materials on the topic:

The latest engine for the Mi-171A3 helicopter automatically adapts to operating conditions

Rostec Holding increased the production of modernized diesel engines for BMP-3, BMD-4M and BTR-MDM

An innovative hydrogen engine with maximum protection has been created in Russia