One of the most important parts of modern aircraft engines, including the PD-8 and PD-14, is the gear, without which it is impossible to ensure the operation of power plants. Russia has mastered the production of the part at the facilities of "UEC-Salut" (part of the United Engine Corporation of Rostec), completely избавившись от иностранных решений.

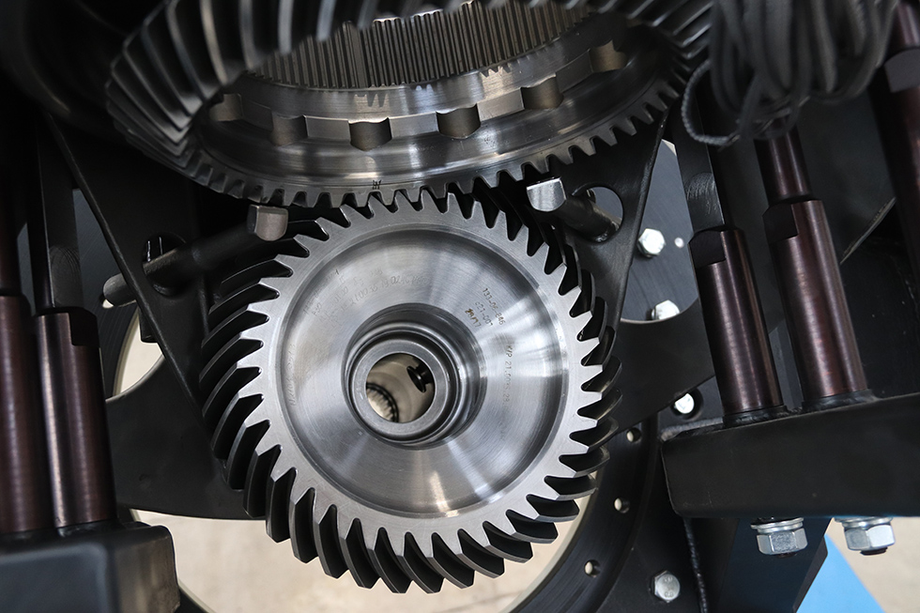

Among engine builders, the gear is also called a gear wheel. It is it that unites the mechanisms in the unit and ensures its operation.

Deputy Chief Technologist of "UEC-Salut" Nikita Kurasov explained that the gear only seems simple externally. In fact, the modern development of mechanical engineering allows you to lay a very complex geometry in the gear rim.

There are gears with a straight tooth — simple workers. Although it would be more correct to say that in an aircraft engine, every detail is responsible and important. But there are simple gears that do not carry high loads, for example, in pumps or rotation sensors. But there are also more important ones, which we call the most responsible. Their manufacture is responsible for the entire operation of the entire engine, for example, the gear of the central bevel gear. They rotate at the same speeds, experience the same loads as the engine rotor itself. Here are the highest requirements for their manufacture, which are measured in microns or even tenths of a micron. These gears are the most interesting.

Kurasov added that the path of any workpiece to the engine begins with mechanical, rough and heat treatment. Then, work is already being done on the semi-finishing turning of the part.

Then, depending on the design, a hardening heat treatment is carried out, which ensures high hardness of the surface of the gear profile. The final stage is grinding, which is considered finishing or finishing.

Approximately 60% of the importance in the manufacture of a gear wheel is given to heat treatment. It is during it that the main properties of the materials laid down in the design documentation are laid down, and high product hardness is ensured. If the heat treatment is performed incorrectly or with a deviation, it is impossible to correct it. This will be considered a defect. The remaining 40% are grinding operations that ensure the accuracy specified in the design documentation.

Earlier www1.ru reported that UEC accelerated the welding of parts of PD-8 and PD-14 engines by 10 times.

Read more materials:

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation