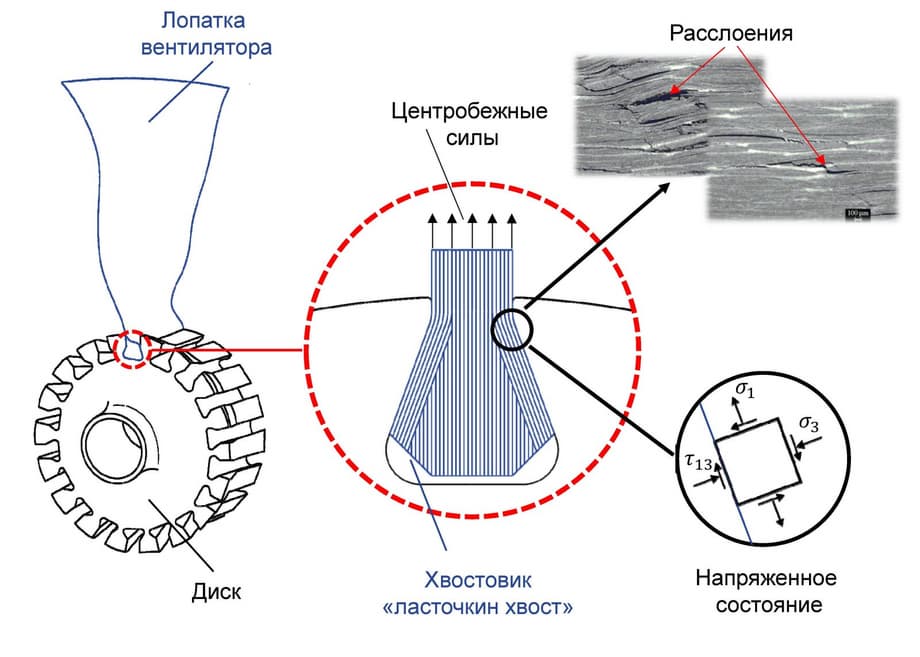

Kirill Guseinov, a postgraduate student at the Department of Technical Mechanics of the South Ural State University (SUSU), has developed the first refined method in Russia for calculating the strength of a composite dovetail joint. It is used to attach fan blades in aircraft engines.

The new algorithm takes into account the nonlinear behavior of the composite under shear and the complex type of stress state. Calculations indicate an increase in the accuracy of strength assessment, which allows optimizing the weight of parts without losing reliability.

Lightening the engine design by tens of percent through the use of composite elements will increase its carrying capacity to 35 tons. In addition, fuel costs and engine sizes are naturally reduced. Every 1% of aircraft weight savings gives an additional 5% of profit.

The development is planned to be used in the design of promising high-thrust PD-35 engines for Russian wide-body aircraft.

Also, the United Engine Corporation has begun to use rotary welding in the production of PD-8 and PD-14 aircraft engines. Thanks to the technology, it is possible to reduce welding time by 10 times.

Earlier www1.ru reported that ODK has accelerated the welding of parts for PD-8 and PD-14 engines by 10 times.