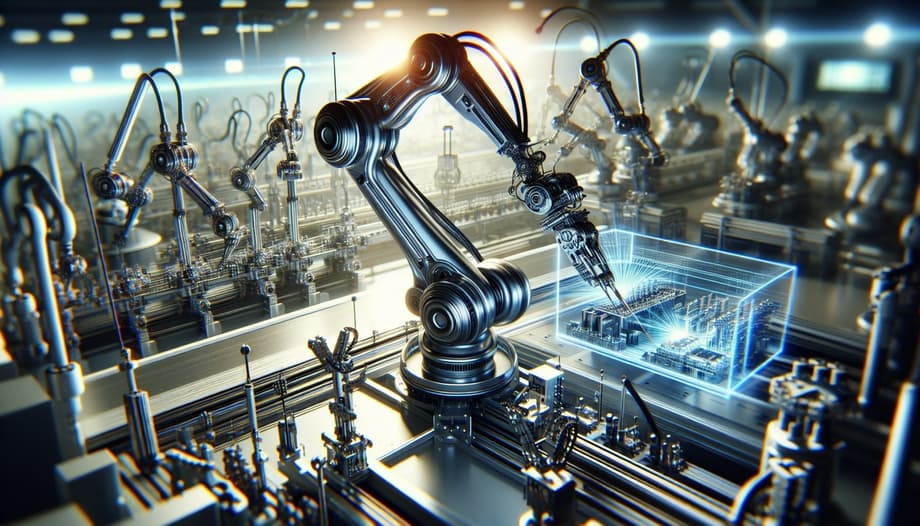

Students from Perm National Research Polytechnic University have created a prototype of an industrial robot that is 30% more energy-efficient. This was reported by the university's press service.

The complex includes a robot manipulator, a control system, sensors, and additional mechanisms. The solution is designed to automate complex processes in various fields, such as industry, logistics, medicine, and others.

Students of PNRPU presented a prototype of a robotic complex, which reduces energy consumption by up to 30%. It has high accuracy, flexibility in adapting to different devices, and is easy to control.

The system is suitable for various tasks: from industrial robots to medical exoskeletons.

The new complex will give small and medium-sized enterprises the opportunity to implement automation, which was previously unaffordable for them due to the high cost of solutions, said Luiza Konogorova, director of the PNRPU business incubator "Growth Dynamics". The payback period of the project will be from one and a half to three years, depending on the industry. The demand for industrial robotics is growing by 15% annually. Interest in energy efficiency is growing worldwide. This makes the development particularly promising.

Earlier, at St. Petersburg Polytechnic University named after Peter the Great, a tactile sensor for robots was created. The device will allow machines to feel the texture of objects and adjust the pressing force.

Read more on the topic:

Production of industrial robots has started in Moscow

Microelectronics manufacturer "Element" has launched a line of industrial robotics

Unique workshops where only robots will work will be created in the Chelyabinsk region