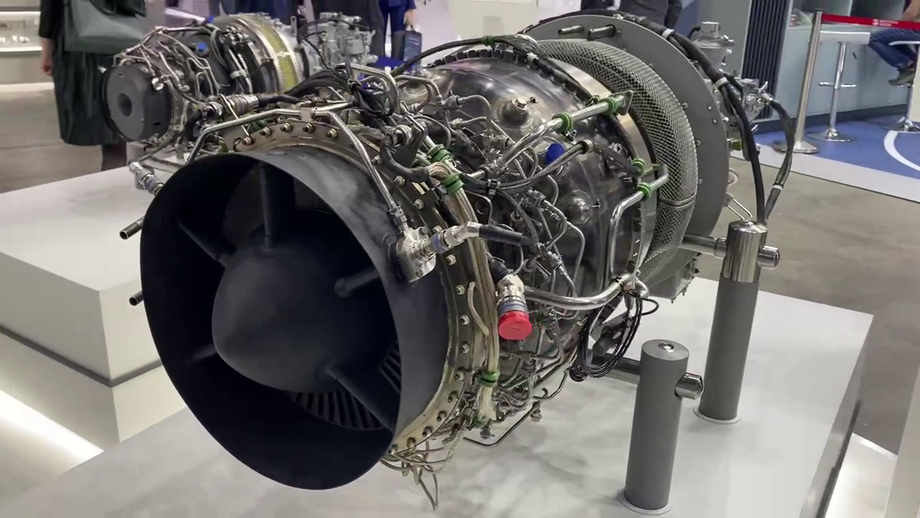

The United Engine Corporation (UEC) is actively developing the production of high-tech parts and assemblies for modern helicopters - Mi-171A3, Ansat-M, as well as VK series engines, including the promising VK-1600. The company's engineers have introduced innovative approaches to the design and manufacture of critical elements: housings, sealing rings, brackets, rocker arms, and other components.

Thanks to the use of digital design technologies and new composite materials, the weight of parts has been reduced by 20% without compromising strength and reliability. At the same time, the full cycle - from concept to flight tests - has been accelerated threefold. This not only increases the competitiveness of Russian helicopter technology in the global market but also strengthens UEC's position as a leader in the field of aircraft engine construction.

These achievements have become possible thanks to the integration of end-to-end digital solutions, including digital twins, automated load modeling, and validation of structures in a virtual environment. This allows for early identification of potential risks, optimization of part geometry, and reduction in the number of physical prototypes. As a result, Russian helicopters receive lighter, more durable, and technologically advanced engines that meet the most stringent requirements of civil and special aviation.