Scientists at Togliatti State University (TSU) have proposed a new way to reduce transport noise, which can improve the acoustic comfort of cars. During bench tests in an anechoic chamber on a 4-cylinder 1.8-liter engine, the technology reduced noise levels by approximately 2-3%.

The essence of the development lies in the use of a vibration-damping material resembling rubber or resin. It absorbs vibrations and converts them into heat instead of emitting sound.

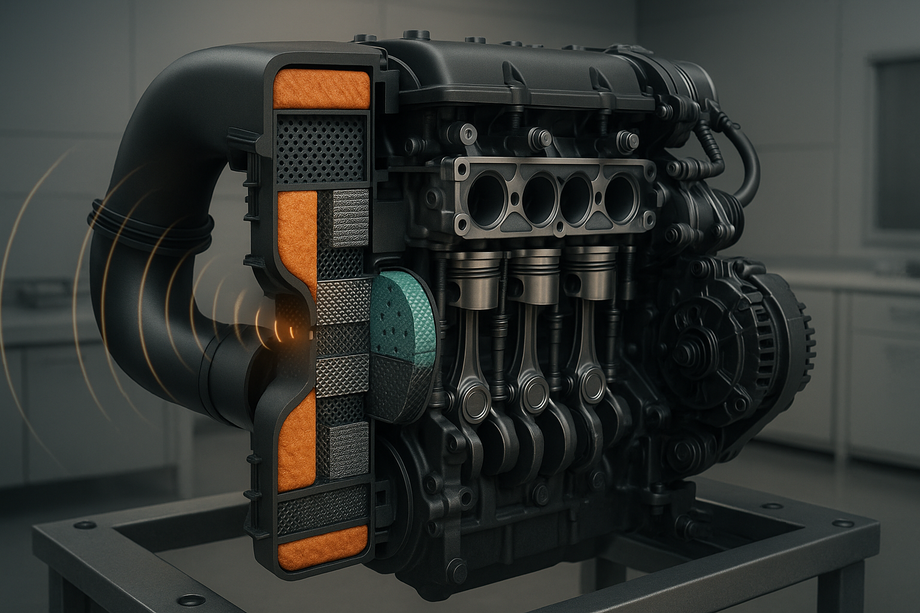

To do this, the intercostal space of the intake system housing is filled with a heat-resistant viscoelastic polymer, and a metal mesh or perforated plate is inserted inside. The rigid elements prevent the walls from swinging, and the polymer dampens the energy of sound waves, which reduces engine noise.

The technology reduces noise both inside and outside the car. It can be implemented in car factories and tuning companies to improve acoustic comfort. The development is especially relevant for cities where transport noise remains one of the main environmental problems.

The new technology takes into account the compromise between lightweight plastic housings, which are advantageous in terms of weight and cost, and their tendency to "re-emit" sound. The new damping scheme makes it possible to maintain the cost-effectiveness of the design and at the same time reduce the noise level.

Read more on the topic: