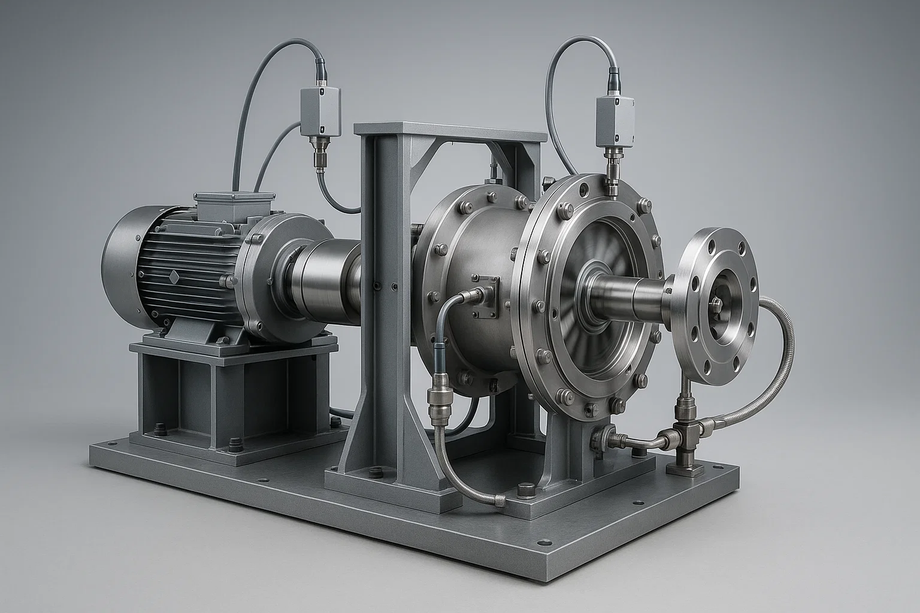

Scientists from Perm National Research Polytechnic University (PNIPU) have improved the technology of turbine test benches, which has significantly increased the accuracy of measurements. The development, protected by patent No. 2842783, reduces the error in determining torque from 15-20% to 4.5-7%, which is especially important for the aviation and energy industries.

The innovation of Perm scientists lies in the use of paired vibration sensors installed at an angle of 90° to each other. They record not only the angle of twist of the measuring spring, but also dynamic parameters - vibrations, temperature, and the frequency of torsional vibrations.

Installing sensors at an angle of 90° to each other allows measuring not only the angle of twist of the spring and the phase angles of its displacement, but also vibration parameters, temperature, and, therefore, the frequency of torsional vibrations. The system automatically compares these data and calculates dynamic coefficients based on them, which correct the value of the measured torque.

Tests have confirmed the effectiveness of the method: at a rotation speed of 14,000 rpm, the error was only 6.9%.

Turbines are key components of aircraft engines, power plants, and industrial equipment. Their reliability directly affects the safety and efficiency of the equipment. Traditional testing methods measure torque indirectly, through the generator power, which leads to errors due to vibrations, friction, and temperature fluctuations.

The technology can be applied in aircraft construction, energy, and mechanical engineering, increasing the accuracy of certification of new engines and reducing the cost of refining designs.

Read more materials on the topic:

Revolution Before Our Eyes: Russia to Develop Next-Generation Aircraft Engines