Specialists of SKB-3 (part of the military-industrial holding "Kingisepp Machine-Building Plant", KMZ) have developed a technology for casting a propeller for a high-speed passenger vessel of the SP15 project. This was reported by the holding's press service.

The customer requires the propeller to be made of corrosion-resistant high-alloy steel. This steel has low fluidity during casting, which leads to defects - incomplete casting and lack of fusion. Considering this, the specialists of SKB-3 will use a special gating system of the funnel type, with top pouring.

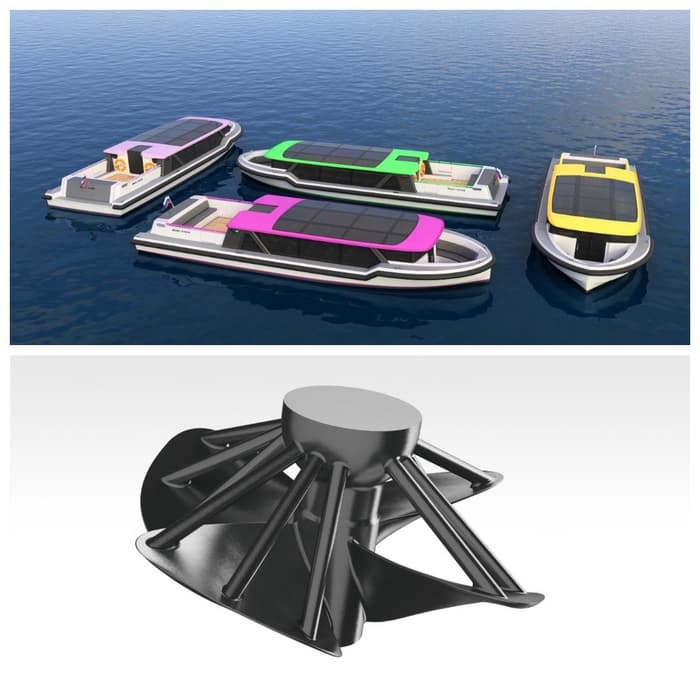

The lead vessel of the SP15 project, developed by AN Marine Consulting, is being built at the Jocore shipyard in St. Petersburg. Its peculiarity is the design, created from polymeric materials. This will reduce the cost of the vessel and speed up its production.

Read more on the topic:

Three-roll plate bending machine FACCIN HAV 2562 implemented at KMZ

Technology for creating parts improved for Russian Diesel engines

Russian alternative to the Italian yacht Benetti Oasis 40M from KMZ named