PC "Marion" has introduced a new line of immersion heaters designed for electroplating processes. The devices are equipped with glass flasks and have become a response to market needs after the departure of foreign manufacturers.

The new heaters complement the existing range: it includes models with titanium and stainless steel AISI 316L flasks. These devices are ideal for operation in aggressive environments, including acids and alkalis used in electrochemical coating.

Each heating element is manufactured manually with careful quality control. During the design phase, engineers determine the optimal resistance of the nichrome wire for the "dry" heating element. After winding the wire onto the ceramic core, the primary resistance check is performed using digital multimeters. During assembly, the parameters are re-checked against the drawings, which eliminates possible deviations.

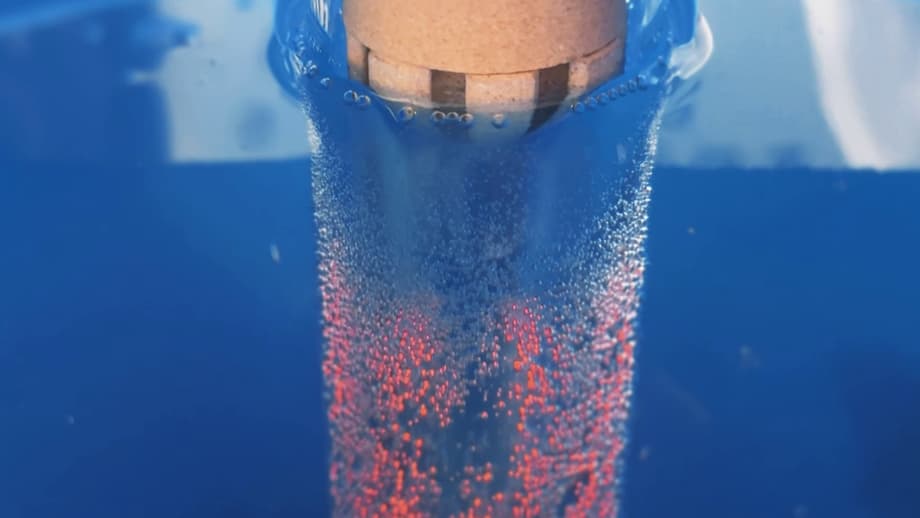

The sectional heating element is fixed inside the flask using mica centralizers, which ensures accurate positioning and prevents displacement during thermal expansion. The finished "dry" heating element is placed in a glass flask, which is sealed with a PETG plastic cap.

The quartz glass flask protects the heating element from aggressive media and allows visual monitoring of its condition without dismantling. Uniform heat distribution ensures stable parameters of electrolytic baths.

Electroplating immersion heaters with glass flasks are indispensable in conditions with high chemical and thermal loads, such as concentrated acids and alkaline solutions. They are in demand in high-temperature processes where other materials may deform. Due to the low coefficient of thermal expansion, quartz glass retains its integrity even with sudden temperature changes, which is critical for electroplating lines.

Read more on the topic:

Industrialists in Russia are almost entirely dependent on foreign machine tools

Now on home

Journalist Alexey Kostylev faces up to 10 years in prison

A corresponding bill has been submitted to the State Duma

The products of the Samara plant are intended, among other things, for shipbuilding and mechanical engineering

Direct laser deposition and selective laser sintering were used in the production

"Buk-M3", S-300, "Tor-2", and "Pantsir" systems are capable of engaging this long-range cruise missile

The devices were manufactured by the Institute of Physical and Technical Problems

The enzyme system in the composition dissolves soft plaque and destroys bacteria

In terms of this indicator, the country is second only to Iraq, Iran and Saudi Arabia

The increase in prices for spare parts is explained by inflation, logistics and the aging of the car fleet

Fake messages were distributed from an unreliable address