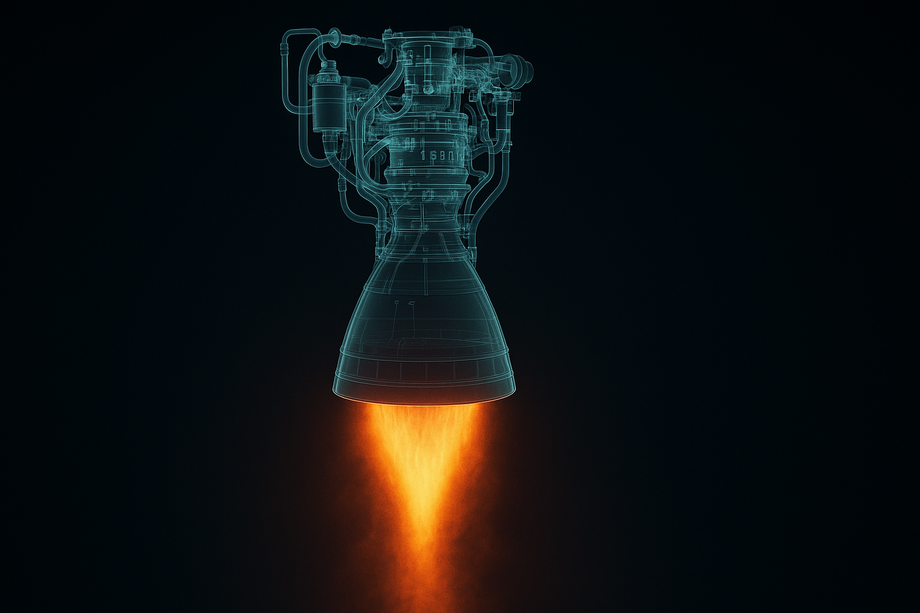

Specialists from St. Petersburg Electrotechnical University (ETU "LETI") and Bauman Moscow State Technical University have developed a technology for precision control of combustion processes in solid-propellant rocket motors (SRMs). The method is based on the use of a compact X-ray system that allows real-time analysis of engine performance parameters without physical opening.

The development is based on a small-sized radiographic system with a radiation source created by ELTECH-Med. The uniqueness of the equipment lies in the size of the focal spot (less than 50 micrometers), which ensures high image detail. To capture rapid fuel combustion, a dynamic detector is used that can shoot up to 30 frames per second. This allows tracking the burning rate, the distribution of fuel components, and the condition of the internal surfaces of the chamber.

SRMs, unlike liquid-propellant counterparts, have increased reliability and simplicity of design, making them key elements in space and defense systems. The new method solves the problem of diagnostics in extreme conditions - at temperatures up to 3000°C and pressures of hundreds of atmospheres. As noted by Professor Artem Gryaznov from ETU "LETI", the technology identifies defects at the production stages, assesses engine wear, and prevents accidents before launch.

Traditional methods of SRM analysis require stopping and disassembling the engine, which increases the time and cost of testing. The innovative approach reduces the risk of human error and improves the safety of rocket technology operation. For Russia, which is actively developing space and defense programs, this technology is a step towards reducing dependence on foreign solutions and strengthening technological sovereignty. In addition, the method opens up opportunities for optimizing fuel composition and designing more efficient new-generation engines.

Tests were carried out on an SRM model, but scientists are already negotiating with enterprises in the rocket and space industry to introduce the development into industrial processes.

Read related materials:

Russian SPT-70M plasma engines running on xenon and krypton will be mass-produced

A new tomograph for checking the quality of aviation parts has been developed in Russia