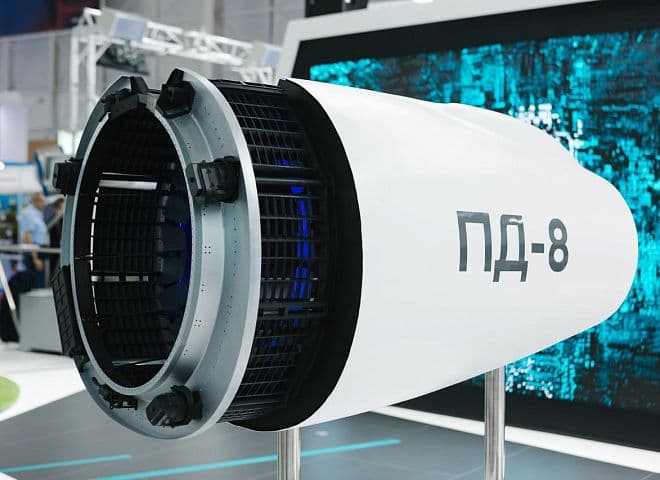

Specialists from Smart Engines have proposed a new method for performing tomography of a jet engine in its entirety - without disassembling it into parts and in a single tomographic measurement on a serial industrial installation. Five million dollars were invested in the development of AI technology.

The specificity of jet engine research is associated with fundamentally different requirements for the materials used to create parts of the "cold" and "hot" parts of the engine.

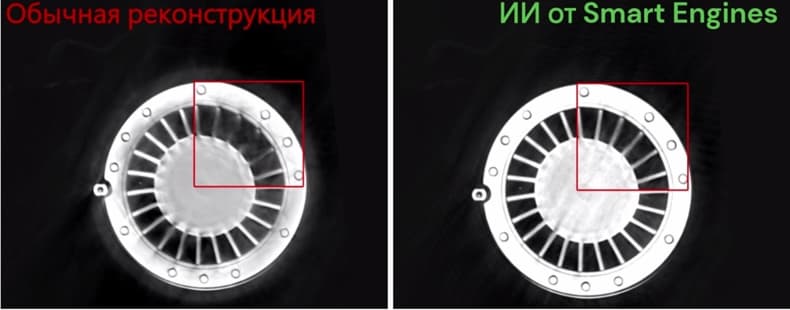

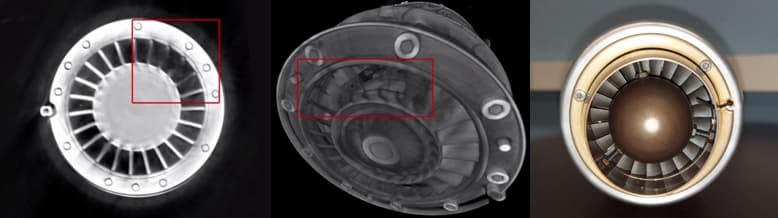

For the "hot" part of the engine, it is important that the parts withstand overloads and high temperatures. The "cold" part, the body itself and the compressor, are created from lightweight materials to minimize the overall weight of the engine. Dense heat-resistant materials are able to absorb all radiation, and light materials are almost transparent. As a result, some real defects are not visible on the engine tomography.

Researchers have proposed a new method of non-destructive testing, combining AI technologies and computed tomography to obtain an objective tomographic reconstruction of all-metal units "as assembled." The technology builds a digital twin of the engine and allows for reliable detection of defects - cracks, voids, delaminations, as well as metal shavings - in a single measurement.

Engine failure is a disaster. To prevent it, it is not enough to check each part. If there is no control of the finished product, the consequences will be sad, although, as Raikin said, there are no complaints about the buttons. With our technology, you can put quality control of assembled engines on the assembly line, bringing their reliability to a new level.

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation

Articles

-

Russian An-124 "Ruslan" Stuck in Canada for 4 Years and Accrues Millions in Fines

26 Jan 2026

-

Coaxial Propellers: How Counter-Rotation Increases Turboprop Engine Efficiency

25 Jan 2026

-

Kazan Aviation Plant Breaks Old System: Tu-214 to be Assembled Like Cars

25 Jan 2026

-

How Engineers and Technicians Are Paid Today in the Russian Aviation Industry: An Overview with Figures

24 Jan 2026