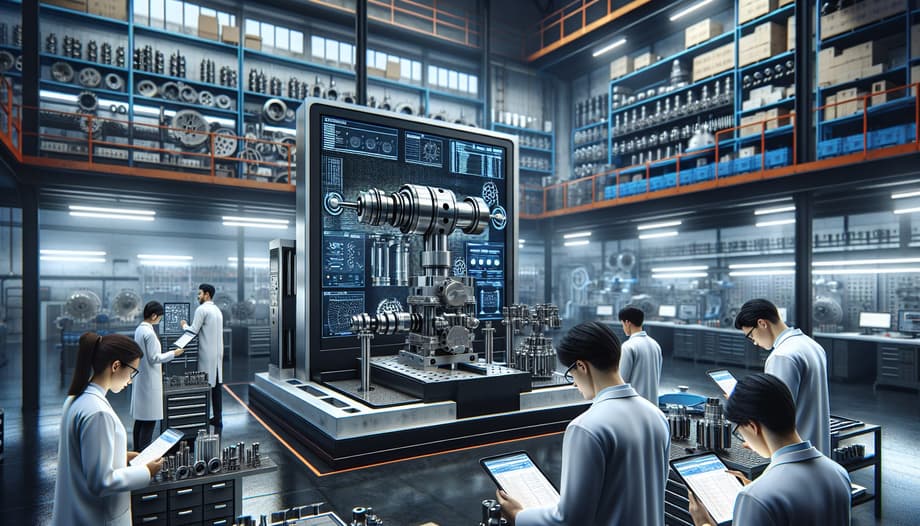

Don State Technical University has created a unique test bench that significantly reduces energy consumption when testing piston hydraulic cylinders by recovering energy. Scientists note that the principle of operation of the installation is innovative: there are no analogues to it in Russia or in the world community.

According to Alexander Rybak, head of the project and professor at the Department of Technology and Equipment for Processing Agricultural Products, the test bench is based on another invention of the university team-a test bench for hydraulic machines of rotational motion "pump-motor."

The tested hydraulic cylinders are included in its pressure line. Energy is recovered due to the double conversion in hydraulic machines of rotational motion and the minimum number of elements that make up the drive. This makes the installation economical.

In this case, the test is carried out in conditions close to the real operating conditions of hydraulic cylinders, while a small amount of energy is spent, which will save the energy used for the test, and, therefore, money. For example, if it is necessary to test high-power cylinders - 50 kW, then under normal conditions the same 50 kW will be spent on this and another 15 - 20% on top for the operation of the system of the stand itself. If we carry out tests on our stand, then the energy consumption will be only 10-15 kW.

New test benches for piston hydraulic cylinders can be used not only in enterprises that produce hydraulic motors, hydraulic cylinders, hydraulic pumps, hydraulic motors, and other similar equipment. They can also be installed at machine-building enterprises that order hydraulic equipment, and at repair enterprises.

Read more on the topic:

ODK Plans to Use New Technologies to Repair PD-14 and PD-8 Engines

YaMZ Presents New Engines - YaMZ-770 Diesel and YaMZ-537 CNG Gas Engines