Scientists from St. Petersburg State Electrotechnical University LETI have successfully applied reverse engineering technology to solve complex import substitution problems. The experiment was conducted in the laser technology laboratory "LETI LaserLab."

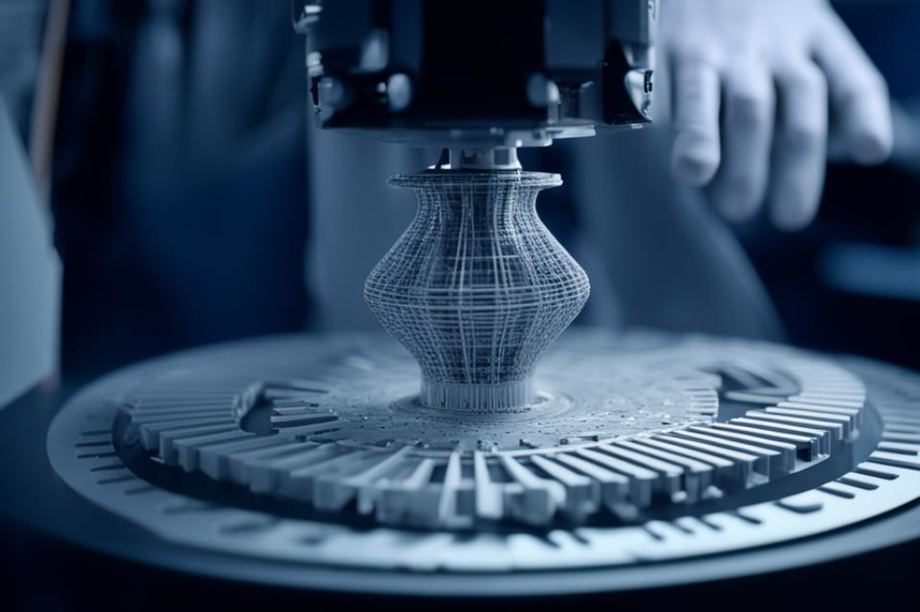

With the help of an advanced 3D scanner, it became possible to digitize objects of the most complex structure and create working drawings for reproducing parts. This method makes it possible to reproduce parts for industrial machines of domestic production, which is important for ensuring the stability of domestic industry.

The experiment was carried out on a foreign-made part of a complex asymmetrical shape, which ensures the operation of an imported machine for industrial mixing of polymers. Such parts are difficult to copy and reproduce by conventional methods, and in this case, the use of advanced digital solutions, such as a 3D scanner, becomes very relevant.

Specialists from one of the St. Petersburg enterprises asked us to help reproduce a spare part for a production machine for mixing polymers. They provided us with a sample of this damaged part, which had become unusable. Using a special 3D scanner and reverse engineering method, we created a three-dimensional computer model from an existing sample, and also made an exact copy of the spare part from stainless steel

Modern technologies, such as 3D scanning and reverse engineering, are becoming key elements of the import substitution strategy in Russian industry. The introduction of such innovative methods makes it possible to reduce dependence on foreign suppliers and ensure the stability of domestic production in the face of sanctions and limited access to manufacturer services.

Previously, LETI scientists developed and patented a prototype of a navigation device for people with partial or complete vision loss based on the method of 2D visualization of sounds.

Now on home

Roman Gusarov stated that the SJ-100 is in no way inferior to Bombardier and Embraer

The production volume in 2026 is planned at the level of 3 thousand units

Aviation expert Gusarov called the rearrangement of spare parts from aircraft to aircraft a normal practice

The project is scheduled to restart in 2026

Robert Agee will try to convince colleagues in Washington to lift restrictions

Roman Gusarov stated that the "carcass" is only suitable as a monument or museum exhibit

The work was carried out in 16 ports of the country since the beginning of the winter navigation of 2025-2026

American F-35A and F-16 fighters took off for a scheduled escort

The roller burnishing process will improve the quality of low-rigidity components and reduce stress in assemblies and units

The aircraft was created in the 90s to replace old Soviet airliners

Navigation in the region is provided by 13 diesel and one nuclear icebreaker of Project 22220