Russian engine manufacturing is entering a key growth point amid the departure of foreign companies and the expansion of its own production capacities. Experts note that the sector is recognized as the most important element of technological sovereignty and is directly related to the development of transport, aviation, shipbuilding, and energy.

According to the Ministry of Economic Development, production growth in mechanical engineering exceeded 11.8% in the first half of 2025, and in the third quarter, transport engineering, including engine production, showed an increase in investment of more than 3.3 times compared to the same period last year.

Experts emphasize that until 2022, Russia practically did not produce engines entirely from domestic components, and import substitution became a catalyst for the development of local technologies. Today, domestic internal combustion engines, gas turbine units, aircraft engines, and diesel engines are demonstrating qualitative progress.

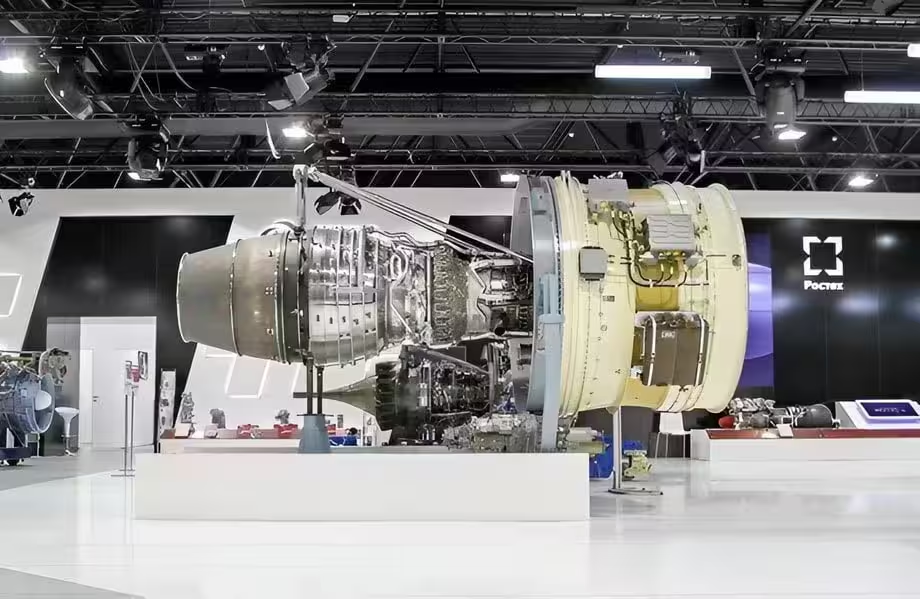

Among the new Russian developments are the PD-8, PD-14, PD-26 aircraft engine lines, gas turbine units for helicopters, and innovative diesel generators. The increase in the production of aircraft engines in recent years has exceeded 50% — from 791 to 1,227 units delivered. The production of internal combustion engines for motor vehicles also increased by 11.5% in 2024, which contrasts with the trend of declining production worldwide.

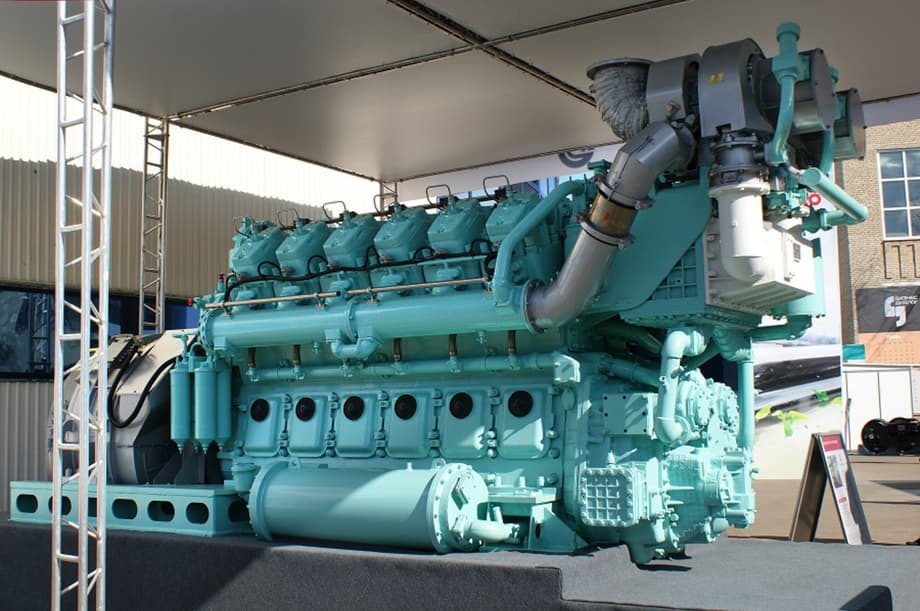

Over the past three years, a number of enterprises, including the Kolomna Plant, the Ural Diesel-Motor Plant (part of the Sinara Group), and the Perm company Aviadvigatel, have carried out a large-scale modernization of production facilities. The Kolomna Plant, a leader in the production of medium-speed diesel engines of new generation types D300 and D500, has developed and implemented new models. The Ural Diesel-Motor Plant presented the UDMZ DM-185 series of diesel engines. The Perm company Aviadvigatel also made a significant contribution to the development of the industry.

One of the main tasks to increase the independence of the industry is the localization of the production of components, including casting blanks and control units. This will reduce dependence on imported components and strengthen the position of domestic manufacturers in the market.

The state continues to support the industry through preferential financing of R&D, simplified taxation, and stimulation of investment in modern engines. However, a critical need remains in the localization of high-tech systems and the development of the component base.

Read more materials on the topic:

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation