Scientists at the Moscow Aviation Institute (MAI) have developed an innovative installation for high-precision processing of parts made of brittle, but extremely hard ceramics and ceramic matrix composites, widely used in the designs of modern aircraft and space systems. The installation is designed for drilling holes up to 10 mm in diameter and is already being tested at one of the aviation industry enterprises.

The key element of the technology is the ultrasonic processing method: high-frequency oscillations in the range of 18–20 kHz (up to 20 thousand micro-impacts per second) are applied to the cutting tool — diamond horseshoe-shaped drills. The oscillations are generated using a piezoceramic transducer, which causes the drill to not only rotate, but also make microscopic reciprocating movements.

Thanks to this approach, the load on the workpiece is significantly reduced, which minimizes the risk of cracking brittle components, and tool wear is reduced many times over. At the same time, the processing quality is maintained at the required level, and productivity increases by an average of ten times compared to traditional methods.

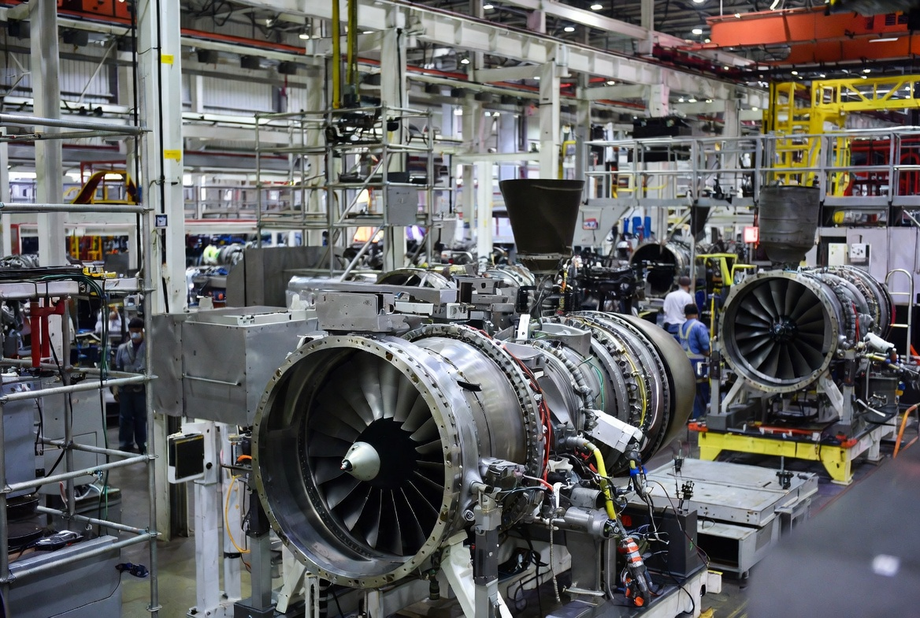

As explained at MAI, the use of this technology is especially relevant in the manufacture of engine components, heat protection systems and load-bearing structures, where ceramic composites are used that can withstand extreme temperatures and mechanical loads, but are prone to damage during conventional machining.

Read more materials on the topic:

- Modernized and returned to service: auxiliary boilers of the 70-year-old icebreaker "Kapitan Belousov" underwent major repairs

- Aggregates of the auxiliary boiler plant were installed on the nuclear icebreaker of project 22220 "Leningrad"

- Centrifugal casting and digital processing — TMH modernized the production of diesel parts