A new metal laser cutting machine has started operating at the blanking production facility of PJSC "Kirovsky Zavod "Mayak" (part of the Kalashnikov concern). This was reported by the company's press service.

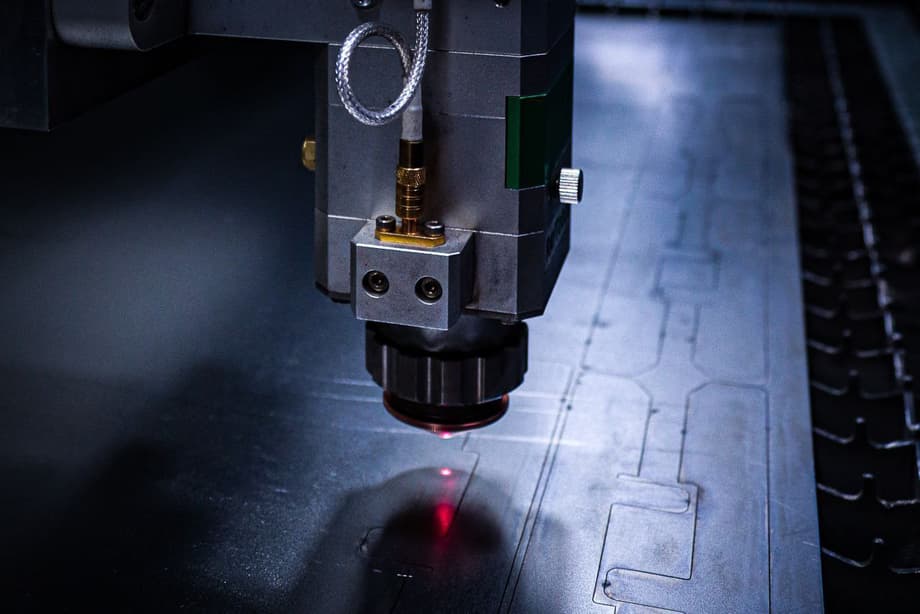

The machine with numerical control (CNC) provides processing of metal workpieces with high precision. A laser beam transmitted through a fiber optic cable to the cutting head allows you to "draw" specified contours on sheets of various metals (aluminum, steel and titanium).

The advantage of laser cutting is the ability to reach the melting temperature on the surface of the material, which eliminates the formation of burrs and build-ups. This reduces the need for additional processing of parts and guarantees their high quality.

Today we use the machine for the production of parts instead of mechanical stamping dies, and the number of part names has already been increased to 50. The machine's performance is high. Depending on the complexity and size of the workpieces, the machine can produce from 300 to 15-20 thousand pieces per month.

At the moment, only one laser machine is operating at the Mayak enterprise. In the future, it is planned to increase their number.

Earlier www1.ru reported that a new machine was launched at the Kalashnikov plant.