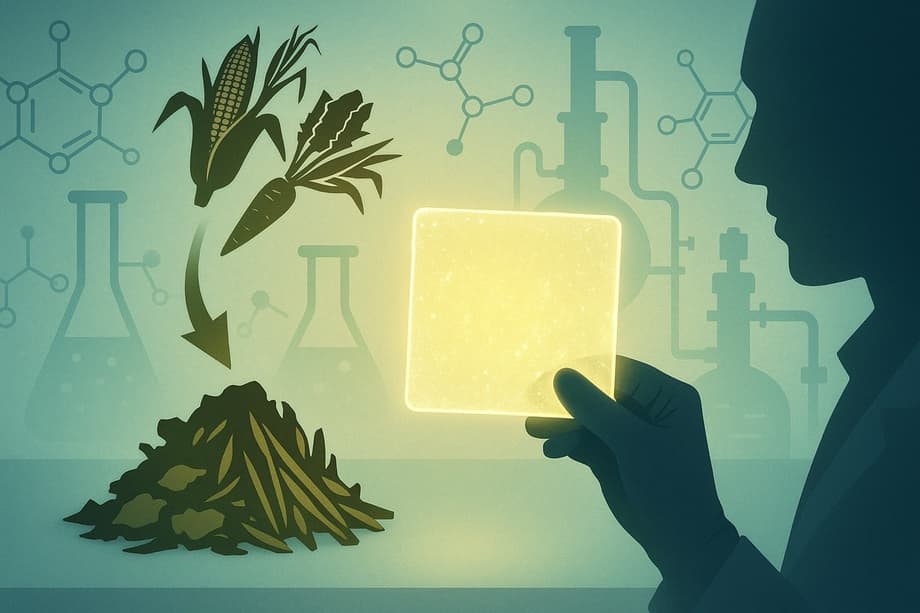

Specialists from Tula State University (TSU) have developed a new polymer based on recycled tree biomass and agricultural by-products. The material can withstand temperatures up to 300ºС and is capable of decomposing naturally, leaving no tails of unprocessed waste.

Today, most packaging and industrial polymers are produced from petroleum products, the reserves of which are limited. Scientists note that in the next 50-100 years, the world risks facing a shortage of such raw materials. Traditional polymers have high resistance, but this is what complicates their disposal: after incineration or mechanical crushing, microparticles of plastic remain, polluting the environment. The new material solves this problem due to its ability to natural degradation.

The polymer was obtained using a catalytic reaction to form triazoles, which are part of the concept of "click chemistry" - a modern approach to the synthesis of organic compounds, which was awarded the Nobel Prize.

The development of such technologies makes it possible to approach a closed production cycle and carbon neutrality, preventing possible crises due to the depletion of non-renewable resources.