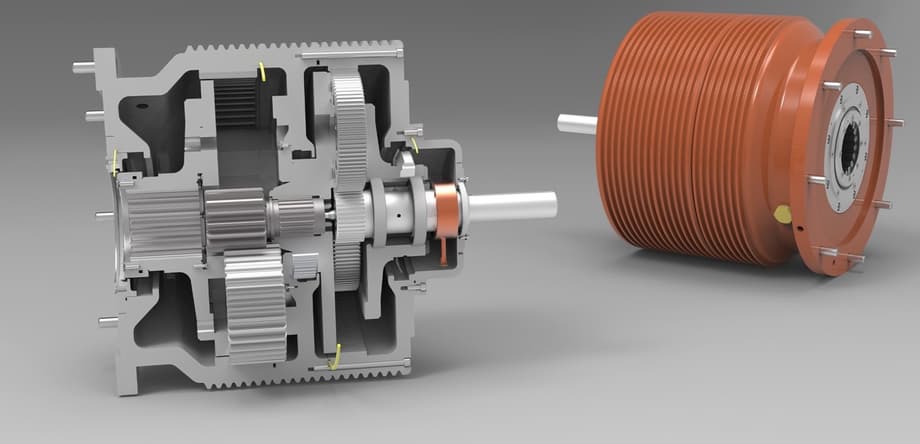

Specialists from SKB-2 of the Kingisepp Machine-Building Plant (KMZ) have performed reverse engineering (recreation from a finished sample without drawings) of a planetary epicyclic gearbox - a key element of a decanter centrifuge.

A decanter centrifuge is used to separate liquids of different densities or to separate solid particles from a liquid. The process takes place in a conical drum that rotates at speeds up to 1400 rpm. Under the action of centrifugal force, heavy particles settle on the walls and are removed through a screw.

Reverse engineering of the gearbox makes it possible to restore or launch the production of high-precision mechanics necessary for the stable operation of such centrifuges, especially if the original parts are no longer available.

Read more on the topic:

TMH has mastered the production of gearboxes for Ivolga electric trains

Suitable for different models: KMZ has created a new gearbox for tractors

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation