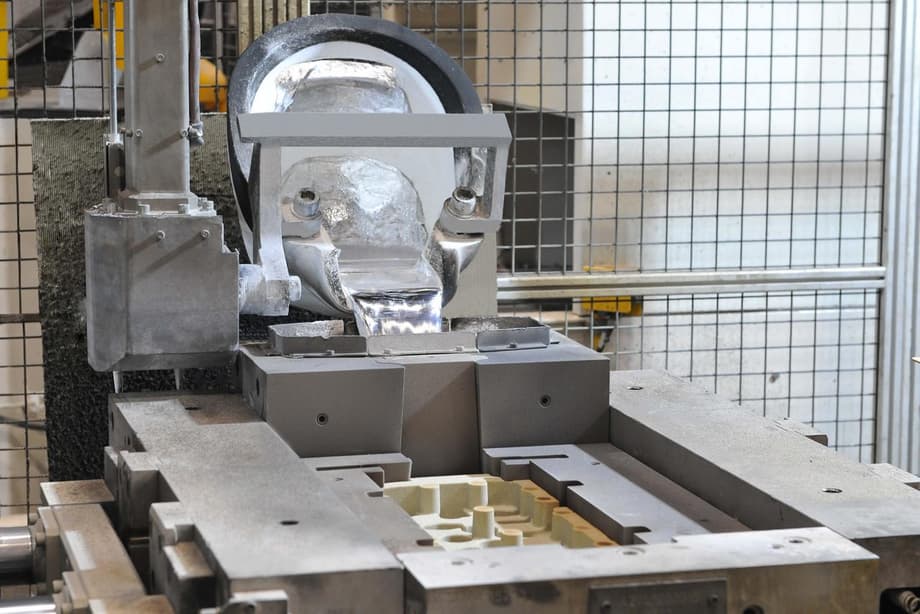

The Non-Ferrous Casting Plant (ZLC, located on the territory of the Nizhny Novgorod Automobile Plant) has improved the quality of "Gazelle" Evotech gasoline engines. For this purpose, the company launched an automated casting complex into a chill mold (metal mold).

Thanks to the new equipment, Evotech engines are fully provided with high-quality components, its capacity allows, if necessary, to produce castings for other engines of this class.

Shrinkage casting inconsistencies are an important problem in the manufacture of cylinder block castings for engines, occurring in the so-called "profit" - the upper part of the workpiece, which after casting is cut off and sent for remelting. At the junction of the future part and the profit, a boundary zone is formed, where defects can occur that affect the quality of the final product.

We have changed the technology so that the most important surface of the head, which is adjacent to the cylinder block and to which particularly high requirements are imposed on cleanliness and tightness, does not fall into this zone. Now it is located at the bottom of the casting, which insures against inconsistencies.

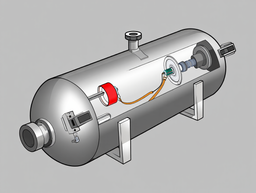

The second important step towards improving the quality of foundry products was the introduction of a water cooling system for chill molds. Each chill mold (metal mold) is now equipped with seven circuits with automatic temperature control and monitoring systems. This allows you to optimize the metal crystallization process.

The casting process has become as automated as possible. It is enough for the operator to install the rods in the chill molds before pouring, and all other operations are performed by robots.

The system also incorporates quality control elements that protect against errors. For example, if the metal temperature does not meet the established technological requirements, pouring will not occur, which prevents defects.

Thanks to the new equipment, Evotech engines are fully provided with high-quality components, its capacity allows, if necessary, to produce castings for other engines of this class.

Earlierwww1.ru reported thattests have started of the new YaMZ-770 diesel engine - 620 "horses" and 6 cylinders.

Read materials on the topic:

YaMZ presented new engines - YaMZ-770 diesel and YaMZ-537 CNG gas

"Tutaev Motor Plant" tested a high-power engine as part of a combine harvester

The most frost-resistant hydrogen engine in the world was developed in Russia