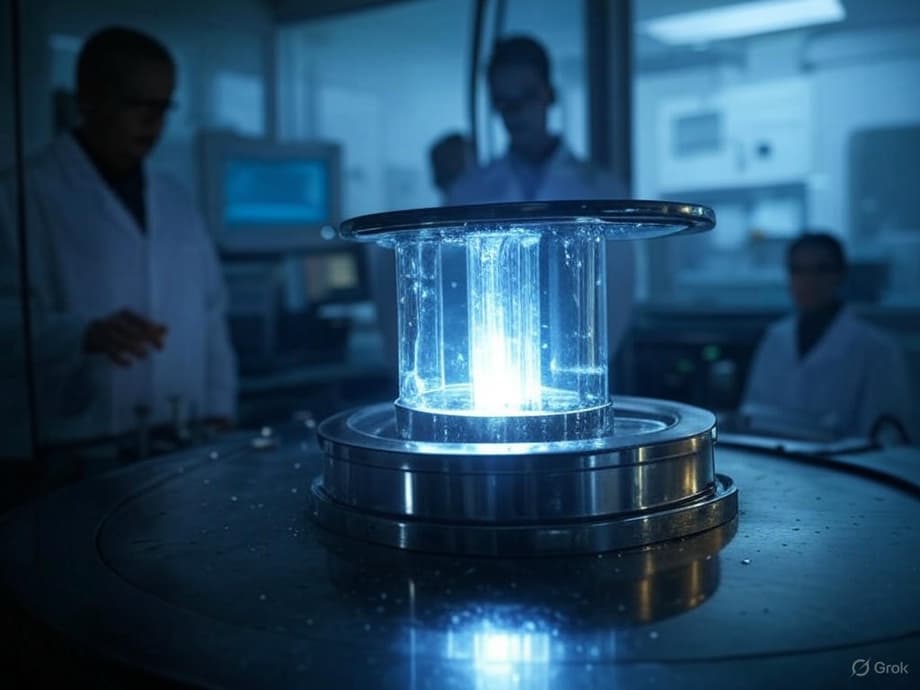

A unique device for testing bearings operating in liquid metal at high temperatures has been developed at the Nizhny Novgorod State Technical University named after R.E. Alekseev (NSTU). This was reported by the press service of the Ministry of Education and Science of the Russian Federation.

Engineers and researchers at NSTU named after R. E. Alekseev have received a Eurasian patent for a new device for testing plain bearings in a heavy liquid metal coolant (HLMC) environment. This coolant is used in fast neutron reactors.

The research is aimed at improving and developing new models of bearings for 4th generation fast neutron nuclear reactors. The bearings are used in circulation pumps that pump liquid lead or a lead-bismuth alloy in research and energy nuclear facilities.

Materials for operation in heavy metal melts are exposed to high temperatures - up to 550°C and are in a corrosive environment. Therefore, the device was divided into two parts - a container into which the removable part with the shaft and the bearing under test is immersed, and the loading device itself.

During operation, a constant pressure of inert gas is maintained above the coolant level in the container. The mechanism transmits force to the shaft in the bearing with high accuracy using a spring-loaded rod through a piston and a rotary motion conversion system. The response force is recorded using a measuring strain gauge.

Earlierwww1.ru reported that a new Russian climate chamber for aviation testing has beendeveloped.

Read materials on the topic:

The first Russian gas compressor passed tests

Photos from the testing of special modules for geological exploration have appeared

TPU has developed fluoroplastic coatings to protect chemical reactors from corrosion