Russian ATF fuel is currently undergoing its third 18-month operating cycle in experimental fuel rods at power unit No. 2 of the Rostov NPP (a branch of Rosenergoatom Concern), completing the first phase of testing. The next phase of its pilot operation will require fuel rods with a chromium coating, which is planned to be used in the production of VVER fifth-generation fuel.

What is ATF fuel?

ATF (Advanced Technology Fuel, or Accident Tolerant Fuel) is nuclear fuel capable of withstanding emergency situations at nuclear power plants and performing its functions without harming the environment.

It remains stable even in the event of loss of coolant and disruption of heat removal in the reactor core. According to its characteristics, accident-tolerant fuel must maintain its integrity for a sufficiently long time without the occurrence of a steam-zirconium reaction that contributes to the release of hydrogen.

Rosatom notes that the use of such fuel brings the system safety and reliability of nuclear power to a qualitatively new level.

How is Russian ATF fuel tested?

The second power unit of the Rostov NPP has become a testing ground for the implementation of the pilot operation program for Russian ATF fuel. Tests are carried out in accordance with international standards for the introduction of innovative nuclear fuel.

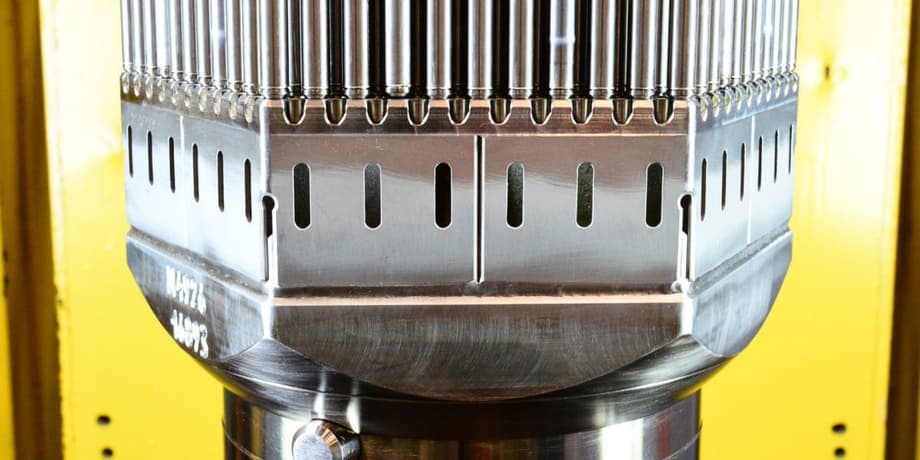

The first stage is the loading of several experimental assemblies with experimental fuel rods into the reactor. According to the international classification, this is the LTR stage - "lead test rods." In 2021, the first three combined fuel assemblies of the TVS-2M design were sent to the reactor core. Each of them had 12 fuel rods in an innovative design.

Six fuel elements are made using a chromium-nickel alloy 42KhNM as a structural material, and six fuel rods are made with shells made of a zirconium alloy with a chromium coating. This technological solution allows either to completely eliminate or significantly slow down the development of a steam-zirconium reaction in the reactor core in the event of an emergency.

The second cycle of operation of such cassettes with experimental fuel rods inside began in March 2023, and the third cycle of operation was launched now, in September 2024.

Fuel cassettes with experimental fuel rods will undergo a standard nuclear fuel operating cycle for Russian VVER-1000 reactors - three fuel campaigns of 18 months each. In a year and a half, during the next scheduled preventive maintenance at the power unit, the fuel will be unloaded from the reactor core, and the innovative fuel rods themselves will undergo a post-reactor research program.

The second stage of testing is the loading of several cassettes completely filled with experimental fuel rods into the reactor. That is, there will be not 12, but 312 in each cassette. According to the international classification, this is the LTA stage - "lead test assemblies." After they successfully pass the operating cycles, Russian ATF fuel will receive international qualification and will be able to be launched into mass production.

For the LTA stage, fuel rods with a chromium coating have alreadybeen developed and launched into production at the Chepetsky Mechanical Plant. In the process of working on them, the state corporation received a technical solution that is important for the development of promising unmanned industries.

It turned out that chromium-plated shells, due to the properties of their surface, can "close" the missing technological link for creating a fully unmanned automated production of VVER fifth-generation fuel - the TVS-5 design. This fuel design for VVER-1200 reactors is specifically designed to exclude a number of technological operations during its assembly, where personnel are still involved, and not just automation. By analogy with the fabrication of fuel for fast neutron reactors, unmanned industrial production is necessary to close the nuclear fuel cycle for standard thermal light water reactors.

This means that in unmanned Russian reactors, not only enriched uranium, but also regenerated uranium and plutonium can be used as fuel.

Read materials on the topic:

114.67 teraflops for predicting disasters: Russian supercomputer "Sergei Godunov" modernized

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation