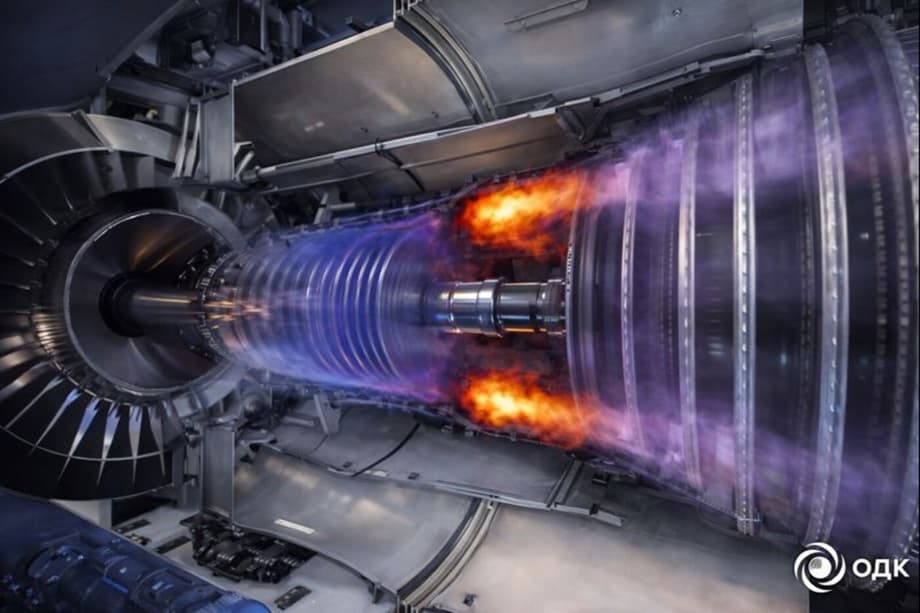

Engineers at the United Engine Corporation (UEC) have revealed the key features of the combustion chamber, the central element of the gas generator in a modern aircraft engine. According to them, if the control system is considered the "brain" of the engine, then the gas generator, which includes the compressor, combustion chamber, and turbine, plays the role of its "hot heart." The temperature of the combustion products reaches 2400-2600 K, twice the melting point of the metals from which the flame tube walls are made.

According to experts, after passing through the compressor, the air is compressed to a pressure of about 50 atmospheres and divided into two streams. The primary stream goes directly to the combustion zone, where it is mixed with finely dispersed fuel supplied through nozzles. The secondary stream is used to cool the structure.

Combustion is initiated by an electrical discharge from spark plugs, after which the process becomes self-sustaining. To prevent the destruction of the structure, secondary air is supplied through hundreds of microscopic holes, forming a protective air film between the flame and the wall, as well as providing its active cooling.

The resulting flow of hot gas is directed to the turbine blades, causing it to rotate. The turbine, in turn, transmits torque to the compressor, closing the thermodynamic cycle. At the same time, a high-speed gas ejection creates reactive thrust.

In modern turbofan engines, a significant portion of the thrust is generated by the outer loop, where air bypasses the combustion chamber and accelerates without participating in the combustion process.