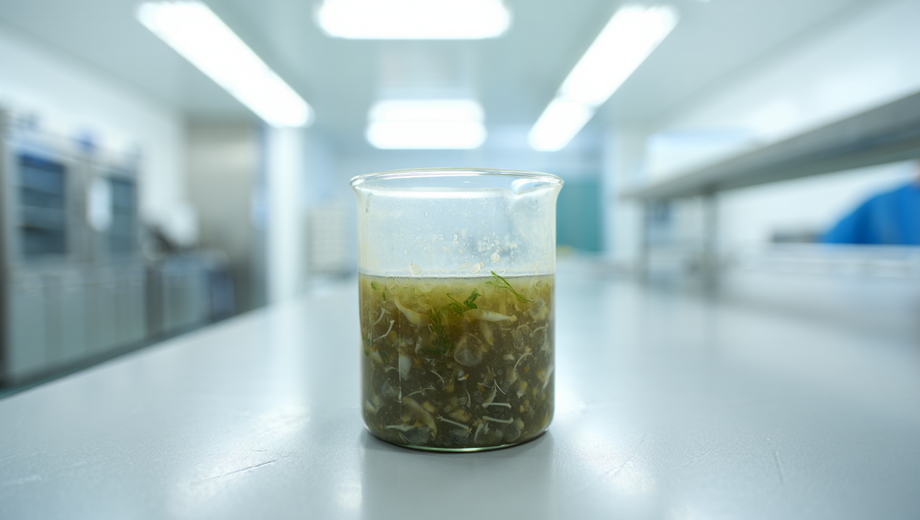

Scientists from the Krasnoyarsk Scientific Center SB RAS (KSC SB RAS), together with the Siberian Federal University, have improved the technology for producing biodegradable plastic - polyhydroxyalkanoates (PHA), using fatty waste from fish processing.

Previously, polymers of a less complex composition, having high crystallinity, which makes processing into high-quality products difficult, were synthesized on this new and promising substrate. Using new technological solutions, it was possible to obtain a more complex type of polymers - copolymers of butyric and valeric hydroxy acids.

The new polymers have reduced crystallinity and high thermal stability. This makes it possible to create more durable and elastic polymer products.

Copolymeric PHAs were synthesized thanks to the development of a special mode of dosing substrates that are usually toxic to cells. Specialists also used a unique strain of bacteria resistant to these substances.

The use of large-tonnage fish processing waste of complex composition for these purposes is a pioneering scientific solution.

The use of fish industry waste in the production of biopolymers is an important step towards reducing the cost and increasing the availability of such materials. This technology simultaneously solves two problems - waste disposal and the production of environmentally friendly materials that can replace traditional petroleum plastics in medicine, packaging and agriculture.

Earlierwww1.ru reported that a new way to create building materials wasdiscovered in Perm.

Read more materials on the topic:

- A building material based on recycled polymer waste has been developed in Novosibirsk

- High-strength, water-absorbing, frost-resistant: a method for creating bricks from waste was invented in Perm

- A new mixture has been developed in Russia for creating building tiles from waste from industrial enterprises