Scientists at the University of Tyumen (UTMN) are creating an experimental plant for processing associated petroleum gas into liquid hydrocarbons and developing an energy-saving deep processing technology. The project is being implemented as part of the "Priority-2030" program and is aimed at the efficient use of hydrocarbon raw materials with minimal environmental impact.

The main goal is to develop technologies for clean energy and environmental protection using the "nature reengineering" approach.

An international interdisciplinary team of specialists from Russia, Syria, and Mexico has been created to model catalytic processes and develop new catalysts.

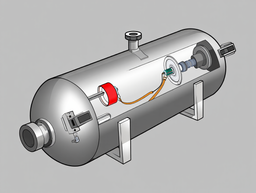

As part of the project, a laboratory unit has already been created for testing catalysts for the Fischer-Tropsch process, documentation has been developed for an industrial unit for processing associated gas, and detailed modeling of gas flows in microfibre catalysts has been carried out.

In addition, scientists have proposed an energy-saving technology for the reverse hydro genolysis process and applied machine learning to select promising catalysts, confirming its effectiveness experimentally.