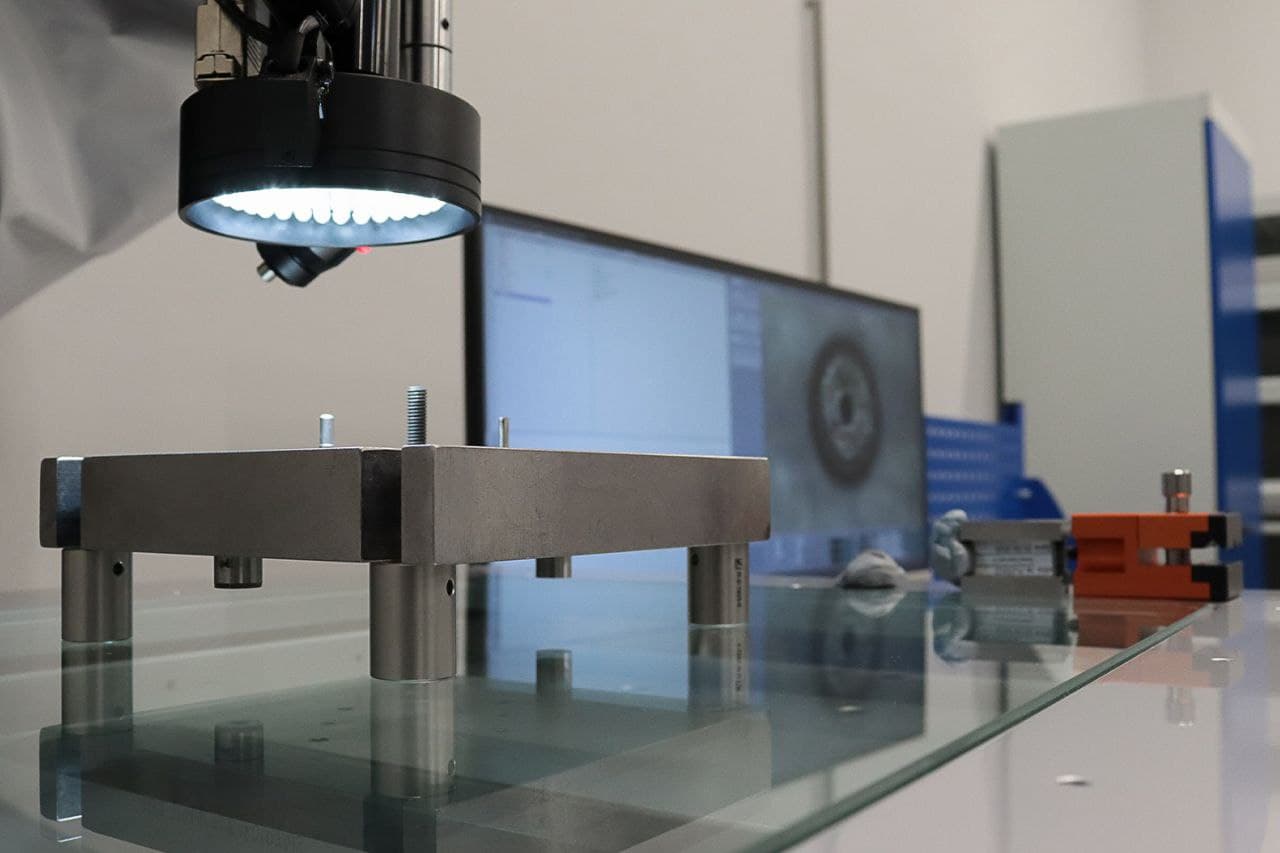

Kirov Mayak Plant (part of the Kalashnikov Concern) has integrated high-precision equipment into the production process. A coordinate measuring machine (CMM) and two video measuring microscopes (VMM) have appeared in the workshops, the concern's press service reported.

A special probe of the CMM examines the surface of parts of any shape and size, and then transmits the image to the screen with an accuracy of up to two microns. The engineer deciphers the resulting image and determines the compliance of the products with the specified parameters.

The CMM recalculates everything quickly and accurately, scanning the part completely, and gives a clear image, according to which we determine unacceptable chips or cracks.

VMM helps to identify defects on the smallest details. The microscope measures angles up to a second. The new equipment brings quality control of manufactured products to a higher level, the concern summarized.

Kirov Mayak Plant serially produces a launcher for the Konkurs-M and Fagot ATGMs. These complexes have already proven their effectiveness in real combat operations.

Read also on the topic:

Improved remote control of the Fagot ATGM is being tested in combat conditions

The modernized Konkurs-M ATGM began to be widely used in the troops

«Victim of ATGMs and drones»: The National Interest criticized the Soviet T-72 tank

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation

Articles

-

Russian An-124 "Ruslan" Stuck in Canada for 4 Years and Accrues Millions in Fines

26 Jan 2026

-

Coaxial Propellers: How Counter-Rotation Increases Turboprop Engine Efficiency

25 Jan 2026

-

Kazan Aviation Plant Breaks Old System: Tu-214 to be Assembled Like Cars

25 Jan 2026

-

How Engineers and Technicians Are Paid Today in the Russian Aviation Industry: An Overview with Figures

24 Jan 2026