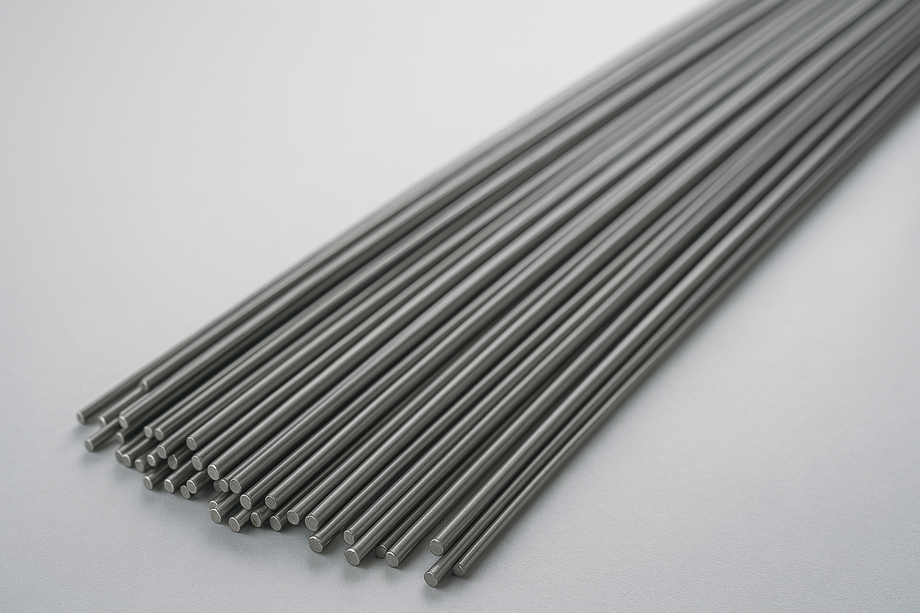

Chepetsky Mechanical Plant (ChMP), part of Rosatom's Fuel Division, has received a patent for the production of titanium and titanium alloy rods. These products are used in medicine to create bone implants, dental prostheses, and surgical instruments.

The technology takes into account the physical and chemical properties of titanium, which requires precise control at all stages of processing. The new method allows the production of rods with a diameter of 5 to 15 mm in compliance with strict international standards.

We are honing our technologies so that Russian healthcare can use domestically produced products of the highest quality. With the growing need for medical semi-finished products, Chepetsky Mechanical Plant is ready to increase the production of components for medicine. Currently, the possibility of creating a separate production site specializing in the production of titanium rods is being worked out. This year, we plan to produce about 40 tons of titanium semi-finished products, from which medical devices for clinics in our country will subsequently be made.

The main buyer of titanium rods is Rosatom Implant, a subsidiary of Rosatom MetalTech LLC. The company produces finished medical products: titanium implants for bone restoration and special surgical instruments for their installation.

Read more materials on the topic:

SFU is developing a biomorphic robot with memristive technologies