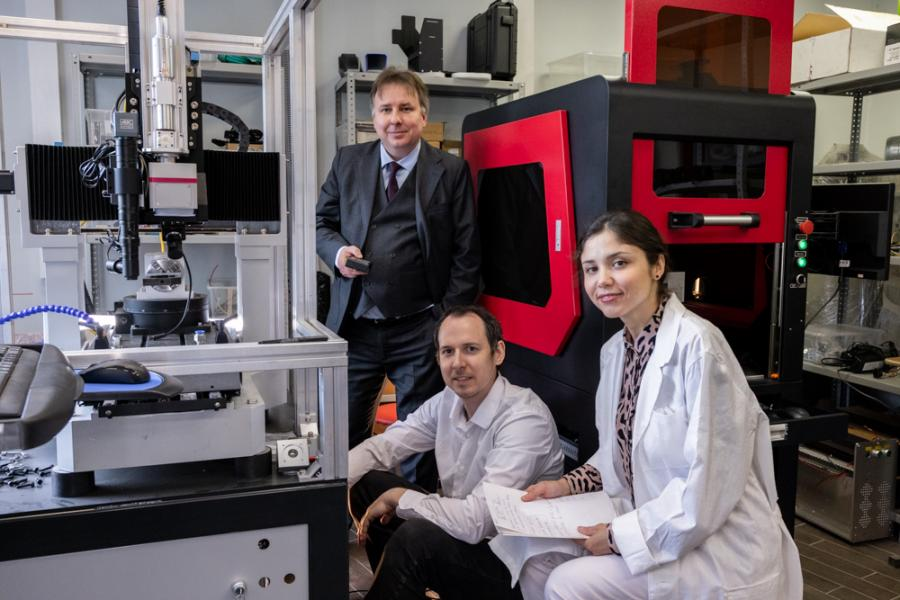

At the Institute of Nanotechnologies in Electronics, Spintronics and Photonics (INTEL) of MEPhI National Research Nuclear University, the youth laboratory "Low-Temperature Co-fired Ceramic (LTCC) Technologies in Microelectronics" is demonstrating significant success in creating domestic analogues of critical electronic components. A team of 17 people, mainly students and young scientists, focuses on two key tasks: developing miniature gas sensors of a new generation and creating unique laser equipment for microprocessing materials - ensuring technological import substitution in instrumentation.

The leading engineer of the laboratory, Maya Etrekоva, laureate of the Moscow Government Prize, is working on sensors based on wide-bandgap semiconductors (silicon carbide, gallium oxide):

We are now actively mastering the technology for producing our gas sensors based on wide-bandgap semiconductors - silicon carbide and gallium oxide. I am sure that very soon such semiconductors will replace silicon, which has been the basis of the electronic industry for more than half a century. In the case of our MIS sensors, new semiconductor materials will accelerate the miniaturization of sensors while maintaining high sensitivity and speed. And a miniature gas sensor integrated, for example, into a smartphone or watch is the future of sensory gas analysis.

Such components are in demand in avionics, space technology and industry.

At the same time, the head of the laboratory, Konstantin Oblov, also awarded with the capital's prize, solved the problem of the availability of specialized equipment for small-scale production and prototyping. His team created a hardware and software complex for four-coordinate laser micro-milling:

Our installation allows small scientific groups to obtain approximately the same result as on industrial lines "sharpened" for mass production. With the help of our equipment, you can repeat operations that are performed in large industries, and also use new materials that were previously difficult to process volumetrically using classical technologies. For example, zirconium ceramics. It is used to create gas sensors - devices for extremely harsh operating conditions associated with recording the quality of fuel combustion processes in gas turbines and diesel engines.

This installation is a key tool for the development and manufacture of domestic ceramic MEMS sensors.

Laboratory staff are actively involved in various international scientific initiatives. One such project is joint work in theDigiMan consortium, together with scientific and commercial organizations from Germany and Israel.

Read more materials on the topic:

The modernized production of the Kiberstal enterprise can halve the import of pipes from China

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation