A team of researchers from MIPT and the Institute for Design Automation of the Russian Academy of Sciences has presented an innovative method for modeling fatigue failure of materials, which is critical for the aviation and mechanical engineering industries. The developed approach combines grid-characteristic calculations with overlapping grid technology, which allows for a detailed analysis of the material degradation process under high-frequency loads. The results of the study are published in the journal Mathematical Models and Computer Simulations.

The new approach developed by Russian scientists makes it possible to model the dynamics of stresses and strains in each loading cycle, as well as track the accumulation of micro-damage. For this, the damage function Ψ is used, which quantitatively describes the degree of material degradation.

The key feature of our approach is the ability to track in detail, cycle by cycle, how micro-damage originates and grows in the material under the action of high-frequency loads. We do not just estimate the final number of cycles to failure, but model the physical process of material degradation itself, taking into account wave effects in each cycle. This gives a much deeper understanding of the mechanisms of fatigue failure.

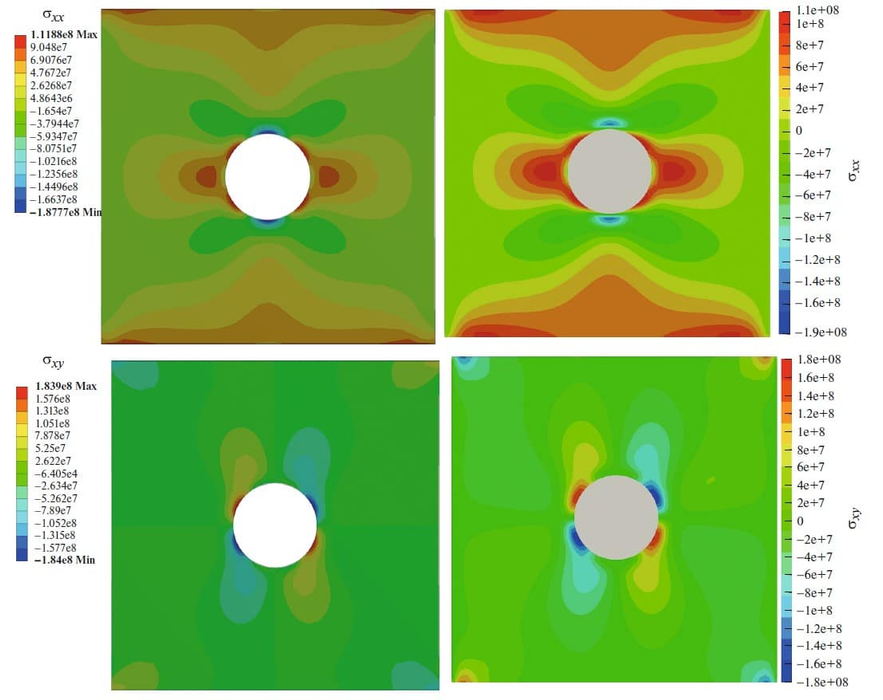

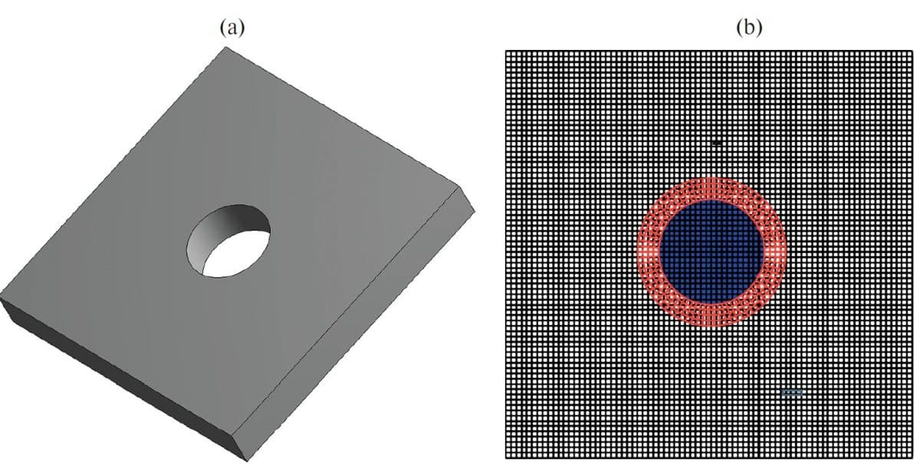

The researchers used the grid-characteristic method in combination with overlapping grid technology ("Chimera"). This allows focusing computational resources on areas with high stress concentrations, such as holes in plates, where cracks most often originate. To speed up calculations, scientists also developed a scaling procedure, reducing the three-dimensional problem to a two-dimensional one. This significantly reduces computation time without significant loss of accuracy. The method has already been tested on the example of a plate with a hole, and its results are consistent with the data of the commercial software Ansys. The technology can be useful in the design of aircraft engines, turbines and other structures subject to vibrations.

Fatigue failure is one of the key reasons for the failure of aircraft engine parts and other highly loaded structures. It develops gradually: microcracks accumulate under the influence of cyclic loads, which ultimately leads to sudden failure. Traditional methods for assessing fatigue strength either use simplified models or focus on already formed macrocracks, ignoring the early stages of damage.

In the future, scientists plan to adapt the method for the analysis of composite materials and complex geometric structures.

Read more materials on the topic:

A unique technetium compound was created by scientists from IHCE RAS

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation