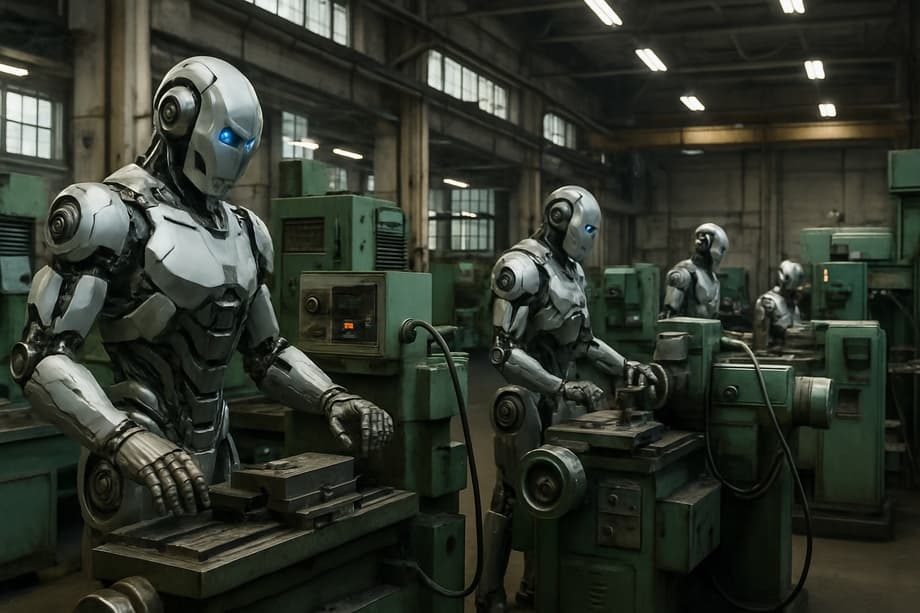

By 2025, the level of implementation of automated systems in domestic companies may almost double - from 4.6% to 8.4%.

According to a study by the KSL consulting group, the key driver will be the shortage of personnel: 15.2% of enterprises cited the lack of personnel as the main limitation for development. This stimulates the transition from extensive methods, such as the construction of new facilities, to intensive methods - the introduction of technologies that increase productivity without expanding the staff.

Despite the potential, the introduction of robotization is associated with barriers. For 25% of organizations, the main obstacle remains high initial costs and a long payback period. Small and medium-sized businesses are often limited by finances, while large companies face the unpreparedness of infrastructure to adapt new solutions. At the same time, 23-24% of enterprises are actively developing the digitalization of processes, including optimizing logistics and managing production cycles.

Experts note that the focus is shifting towards flexible technologies that allow you to quickly adapt to changes in demand, assortment or delivery conditions. The emphasis is on systems covering the full cycle of operations - from planning to execution. Such solutions are especially in demand in sectors with high market volatility.

Read materials on the topic:

New industrial robots with AI will be produced in Moscow

How robots and "smart systems" simplify people's work, told in the Moscow Innovation Cluster

Keeping up with the times: a fundamentally new scheme for bionic legs was created in Russia