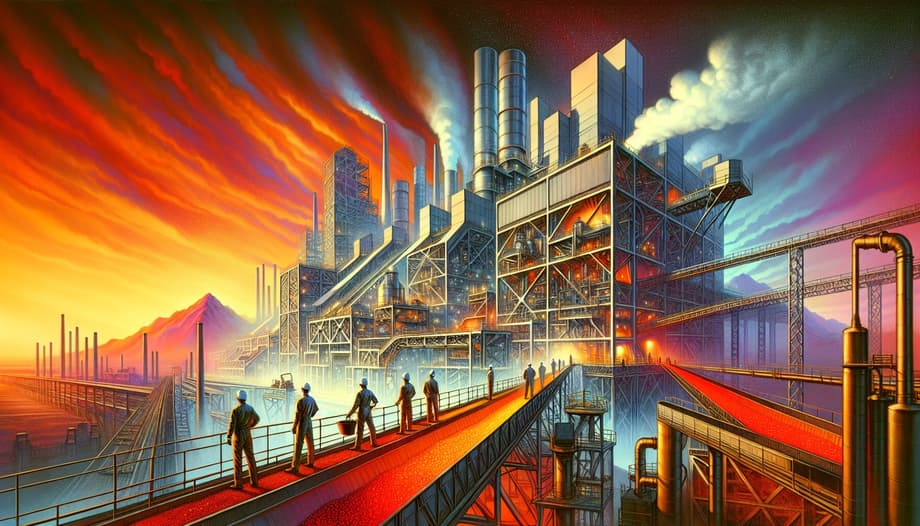

Employees of NRU "MEI", together with PAO "Severstal", have created and patented an innovative method of dry quenching of coal coke, which is actively used in the metallurgical industry. According to the press service of the Ministry of Science and Education of the Russian Federation, this technology can significantly reduce coke losses and reduce the concentration of combustible gases, which, in turn, significantly increases the level of safety in production.

The method involves creating a closed cooling circuit for hot coke using gas, which is 92-100% nitrogen. This gas is obtained at an oxygen station from air using special installations. The nitrogen that remains after this process is used in the system.

During operation, the gas circulating in the circuit is replaced with nitrogen. This reduces the amount of combustible components in the system and, as a result, reduces coke losses. In addition, this approach increases the efficiency of the installation.

The main advantages of the technology are that it prevents the interaction of coke carbon with oxygen, which minimizes carbon loss. If previously the carbon loss reached 2-6%, the new system reduces this figure to 0.2-0.9%.

The technology of dry coke quenching using technical nitrogen is an important step forward in the development of the coke chemical industry. It not only increases the energy efficiency and safety of processes, but also contributes to saving raw materials and energy resources.

Earlier, a group of physicists from MIPT conducted a study onthe interaction of piezoelectrics with slit electroacoustic waves. The results obtained can be used to create unique sensors that can detect microorganisms and viruses, as well as measure the properties of various materials.

Read also on the topic:

New machine learning algorithm created at MIPT

Tomsk scientists have patented a technology for creating optical radiation control elements

Breakthrough in the field of AI: MIPT has developed a neuron that reduces computational costs