The Center for Additive Technologies (CAT, part of the United Engine Corporation) has launched a domestic X-ray computed tomograph.

The equipment will allow quality control of aircraft engine parts up to 1.5 m in size and weighing up to 100 kg.

The device is used to detect and analyze internal volumetric defects in metal products. It also detects external imperfections that are difficult to detect during visual inspection.

In addition, the equipment can control the dimensions of internal elements and channels of blanks, and create 3D models of objects for subsequent reverse engineering.

Earlier www1.ru reported that a sample of the PD-35 aircraft engine passed the first stage of testing.

Read more on the topic:

Rostec will start growing parts for an advanced aircraft engine

It became known when the serial production of Russian engines for the An-124 "Ruslan" will begin

Now on home

The maneuvers also involved an Il-78 tanker

Tests were conducted at extremely low temperatures

The development can be integrated into any communication systems from Agat-System

The FindFace Multi system analyzes images from more than 250 cameras on the city's streets, squares, and parks

3D printing specialists regularly send cargo to the front lines

The ship called at St. Petersburg on January 16, leaving the Egyptian port of Damietta

Athens intends to become a transit country for American gas

Imports from China Account for a Third of the Market, Domestic Factories are Idle

The company is betting on autonomous underwater vehicles and unmanned vessels

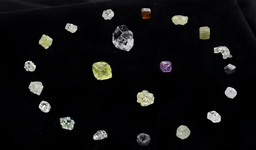

The collection includes 238 fancy colored stones - purple, green-yellow, orange-brown

The Ministry of Internal Affairs described multi-stage schemes that induce victims to transfer funds