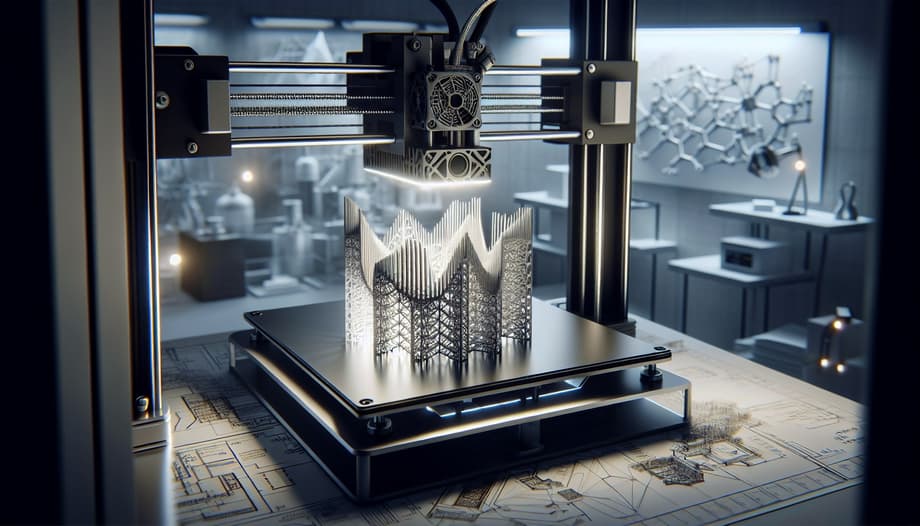

At the National University of Science and Technology "MISIS" (NUST MISIS), an innovative approach has been developed and patented to prevent the appearance of defects in aluminum alloys during the production of parts using 3D printing and laser melting. This was reported by the university's press service.

Scientists have for the first time applied a combination of zirconium, scandium, titanium, and boron to process high-strength aluminum alloys. These modifiers contribute to the formation of smaller crystal grains and prevent the formation of undesirable columnar structures. The latter lead to defects in 3D printing and laser melting of aluminum materials.

The new method makes it possible to prevent defects caused by uneven distribution of alloying elements. Specialists at metalworking enterprises often encounter this problem, as well as when using 3D printing, welding, surface treatment and other types of laser melting.

The melting areas were proposed to be heated to a temperature of 350°C-480°C. This approach made it possible to take into account various mechanisms of action of modifiers and to use their individual properties as efficiently as possible. An additional annealing stage increased the homogeneity of the material and prevented cracking of the alloy.

We recorded a decrease in grain size by 15-30 times both in the as-cast state and after laser melting. This effect has a positive effect on the mechanical properties of the material.

The development will allow the production of defect-free parts of internal combustion engines and high-tech body parts.

Earlierwww1.ru reported that Moscowcreated a digital model to improve the processing of mining waste.

Read materials on the topic:

Rostec showed how 3D printing of aircraft engine parts works

Russian military adapted 3D printers for the production of ammunition

A new Russian 3D metal printing technology has been patented