Aircraft engines undergo thorough inspection before getting on the wing of an aircraft after leaving the assembly line. The work is carried out with accuracy down to the micron, because in the case of aviation, people's lives are at stake.

All aircraft engines produced by the enterprises of the United Engine Corporation (part of Rostec) undergo a standard test cycle before being sent to the customer. It produces engines for space programs, almost all domestic civil and military aviation, as well as marine and land-based gas turbine units.

Let's start with a visual inspection

New power plants undergo long and large-scale certification tests before being put into series production. Such checks are not required for aircraft engines that have already been certified, but they are also subjected to detailed analysis before being sent to customers.

The first stage is measurement and visual inspection. Inspectors at this stage inspect the engine for external defects: traces of corrosion, cracks and scratches. Fasteners, all connectors and other external parts of the engine are also inspected.

Strict control is important because deviations from the norm or defects can affect the engine's performance and safety. In particular, the engine efficiency will decrease by 1-2% if the compressor or turbine blade is made with a deviation of only 10 micrometers from the specified size.

As a result, increased vibrations or excessive turbulence will be created. In addition, such vibrations will provoke premature wear of bearings, which can lead to engine failure in flight.

Check, not destroy

The next important step is non-destructive testing, which includes magnet powder and eddy current testing methods, radiography and ultrasonic flaw detection. With their help, hidden defects in the material are detected - delamination, voids and cracks that cannot be detected with the naked eye.

Welcome to the stand

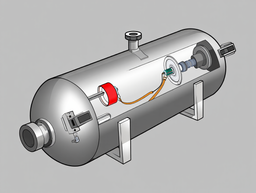

After completing a set of control operations, the engine is sent to bench tests, where specialists adjust its operation and monitor the temperature in working condition.

Then the engine runs on the stand in various modes, simulating real operating conditions. The engine's operating parameters are checked, such as temperature and pressure at the inlet and outlet of the turbine and compressor, noise and vibration levels, and fuel consumption.

These data are then analyzed to ensure that the engine meets all requirements. One of the most stringent tests is the test for ultimate endurance and ultimate power.

The engine is started at maximum values to check its ability to withstand extreme loads and to identify any design or material flaws that may lead to unit failure in the future.

A step on the way to the sky

At the final stage, engine tests are carried out at the test station of ODK-Perm Motors. Specialists check the main indicators: thrust, power, engine characteristics when operating in different modes, carry out temperature measurements and pressure measurements of various liquids.

Testing aircraft engines before installation on an aircraft is a costly and delicate process that requires rigor and extreme accuracy. However, thanks to such scrupulousness, it is possible to minimize risks and confirm that each engine produced is fully ready for flight operation.

Read materials on the topic:

From Moscow to Antalya and Bodrum on Superjet-100: Red Wings launches premium flights

Fly, aviation, large and small - Russia is preparing to launch air taxis

Now on home

The 136 hp engine successfully started at -30 ℃

Experts visualized heavy vehicles of the future

The main feature of the exhibit is its ability to move under its own power

Specialists from SUSU and NPO "NTES" took into account logistics needs: the weight of the cargo is displayed in real time

The new method provides a temperature regime for drones in the aircraft's cargo compartment

The main purpose of the development is to store and supply working fluids to the pipelines

Combat vehicles transformed into APCs with serious drone protection

"ODK-Klimov" Reduces Financial Claims Against Kazan Helicopter Plant

Russian scientists have recorded a fresh flare zone in the south of the Sun

Army's "Boomerang-10" Implements Target Acquisition Function

The price of the aircraft without engines starts from 233 million rubles

The operation takes only 12 seconds per wheel