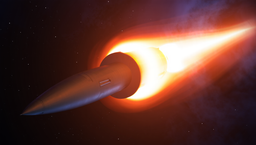

Modern aircraft engines achieve incredible efficiency — but at the cost of extreme conditions inside the turbine. The gas temperature at the inlet to the high-pressure turbine exceeds 1600 °C, which is significantly higher than the melting point of even the most heat-resistant alloys. However, the turbine blades not only survive — they maintain their shape and strength, ensuring reliable engine operation for thousands of hours. How is this possible? Specialists from the United Engine Corporation (UEC) explained.

Experts emphasize that modern gas turbine engines would be impossible without advanced cooling systems. The fact is that metal begins to lose strength long before melting — already at 900–1000 °C, its structure weakens and its shape deforms. To avoid this, engineers use a comprehensive approach that combines new generation materials, protective coatings, and multi-level cooling.

The basis of the blade design is nickel superalloys alloyed with elements such as tungsten, cobalt, chromium, molybdenum, as well as rare metals — rhenium and ruthenium. In some compositions, the proportion of alloying additives reaches 15%. For additional protection, thermal barrier ceramic coatings are used, which reduce heat transfer into the metal and protect against hot corrosion.

But even these measures are not enough. Therefore, the convective-film cooling system plays a key role. Cold air, taken from the intermediate stages of the compressor, is directed inside the hollow blade through a complex network of microchannels. Passing through them, it removes heat from the inside. Then this same air exits through hundreds of microscopic holes evenly distributed over the surface of the blade. The exiting jets form a thin gas film that shields the metal from direct contact with the hot gas flow.

Thanks to this technology, the temperature of the blade itself can be 400–500 °C lower than the temperature of the surrounding gas — even if the latter exceeds the melting point of the material.

The production of such blades is the pinnacle of technological excellence. The internal geometry of the channels is designed taking into account aerodynamics and heat transfer, and the location of each hole is calculated with micron accuracy. The enterprises of the United Engine Corporation (UEC) possess advanced casting methods, including directional crystallization and single-crystal technologies, which make it possible to create parts that can withstand extreme loads.