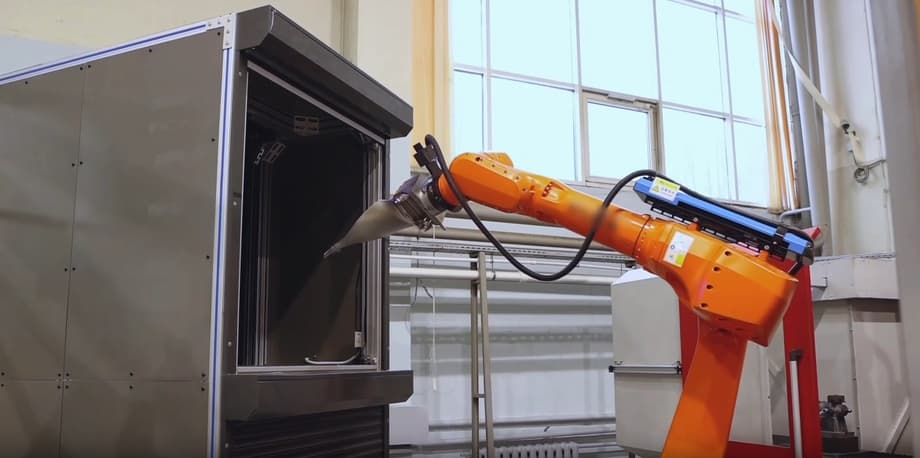

A robotic complex for adaptive grinding of large gas turbine engine blades has been put into operation at UEC-Saturn. The development was created by specialists from P. A. Solovyov Rybinsk State Aviation Technical University and is designed to automate key operations.

The machine combines grinding, washing, and profile control of parts using a non-contact optical system. The implementation reduces the overall processing cycle by 1.5–2 times and increases the throughput of the section.

Igor Ilyin, the chief engineer of the enterprise, said that the complex expands the capabilities of the center of competence in the manufacture of blades and provides new experience in the robotization of production.

Among the other 35 robotic installations, it stands out for the scale of the area occupied and the amount of integrated main and auxiliary equipment.

The equipment automatically selects the processing mode. The role of the operator has been reduced to loading parts and monitoring results, which reduces the influence of the human factor.

UEC-Saturn is the main manufacturer of the PD-8 engine for the SJ-100 civilian airliner. At the end of 2025, they introduced the latest laser installation for cutting parts for aircraft engines.

Read more materials on the topic:

- Withstand the impossible: turbine blade cooling technologies have reached a new level

- Russia will demonstrate more than 200 samples of military products at the UMEX 2026 exhibition in the UAE

- How the combustion chamber of an aircraft engine is arranged: UEC engineers explained the principle of operation of the "hot heart"