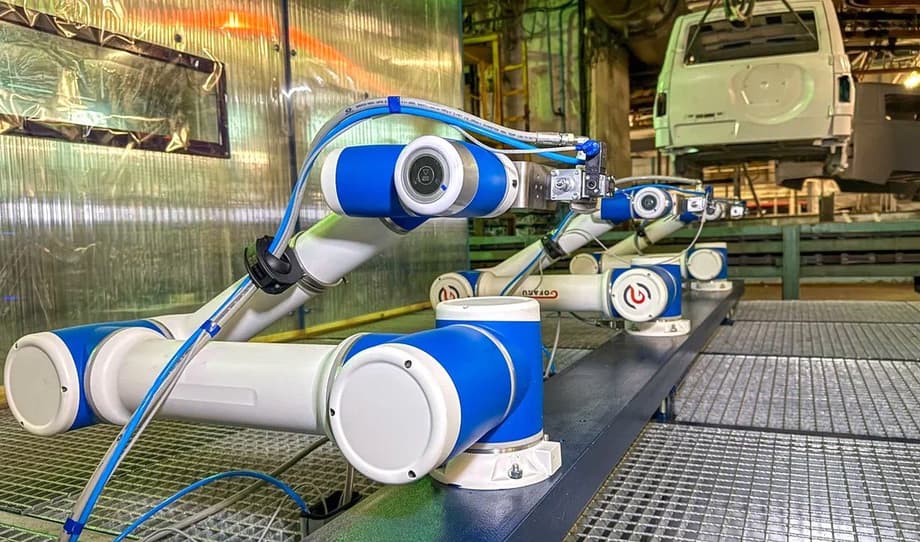

Specialists at the Ulyanovsk Automobile Plant (UAZ) have completed the installation of new industrial robots in the paint production facility. The robots will be used to apply mastic to the underbody of UAZ vehicles and the partner brand Sollers. They will replace up to 70% of manual operations, ensuring the stability of the technological process.

Automation will allow for a more uniform and precise application of the protective layer, minimizing the human factor. This will improve the quality of anti-corrosion treatment, enhance noise and vibration isolation of the bodies, which will directly affect the comfort and durability of the vehicles in operation - especially in Russian conditions with harsh climates and poor roads.

The introduction of robots has become a key stage in the UAZ's phased modernization program, aimed at import substitution and increased efficiency. Detailed technical characteristics of the equipment (including robot models and software), as well as data on performance, are promised to be disclosed later - after full configuration and the line reaching its planned mode of operation.

Read more materials on the topic:

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation