The Institute of Thermal Physics of the Siberian Branch of the Russian Academy of Sciences has developed a unique prototype technology for ultra-precise 3D printing of metals from the gas phase. This was announced by Anton Meleshkin, one of the authors of the development.

Existing printing technologies are more often based on sintering metal powder using a laser. The more complex the product required, the smaller the granules should be. This leads to an increase in cost, limits the accuracy and geometry of products.

We have a unique technology, we create conditions when the metal is in a gaseous state. We take it, shine a laser, and all the metal that is in the air in a gaseous state begins to settle in the place where the laser shines.

The new technology allows for greater accuracy in the printing process by determining the diameter of the laser spot.

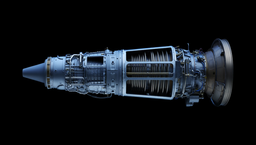

This is relevant for aerospace objects: small turbines, elements made of refractory metals. Also for microelectronics elements.

Scientists have already obtained samples of the first products made of copper, for the creation of which a low-power laser (3 W) and gaseous precursors were used. In the future, it is planned to develop a printer for printing from the gas phase. This technology will also allow the production of biocompatible implants for medicine and the creation of nanostructures and functional coatings.

Earlier www1.ru reported that a new Russian 3D metal printing technology has been patented.