Scientists from Perm Polytechnic University (PNRPU) have presented a new method of intelligent 3D printing of large-sized parts. The development was created jointly with "F2 Innovations" company and has already been tested on serial equipment.

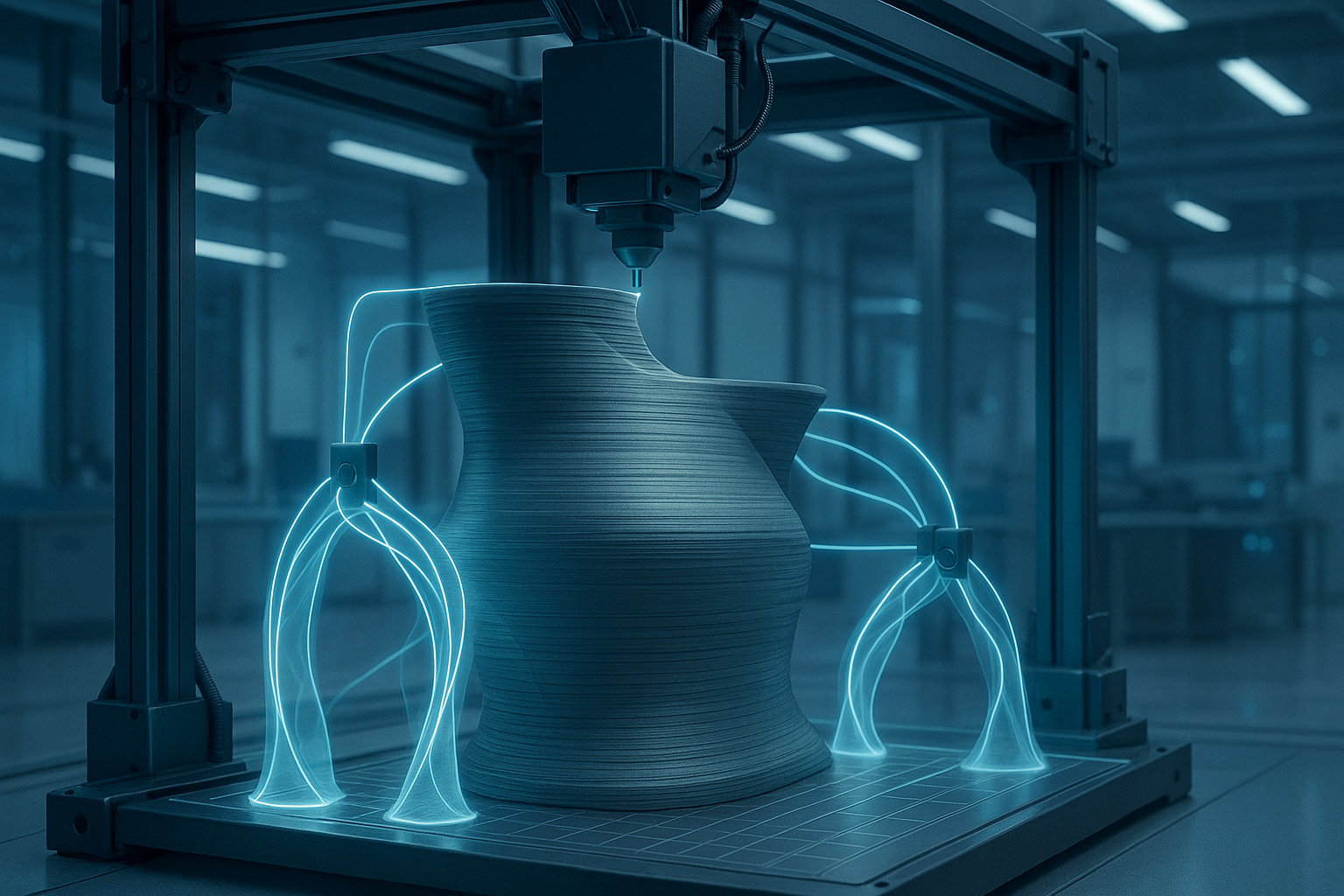

The main innovation of the technology is the use of "smart" mechanical supports integrated directly into the design of the 3D printer. These elements automatically support the overhanging parts of the product during printing, moving synchronously with the extruder, and then are removed without leaving traces on the surface. This approach avoids deformation, increases accuracy, and allows printing more complex shapes.

Unlike traditional supports, which are printed from the same material as the part itself, Perm engineers used independent movable elements. Their shape can be changed by folding or moving, which reduces the load on the not yet hardened polymer. This opens up opportunities for printing large parts with horizontal layer orientation or at angles of 45° and 90°, where conventional methods cannot cope.

The control system determines in advance where reinforcement is needed and directs the mechanical elements to the right place. As a result, the process proceeds continuously and without defects

Similar technologies are in demand all over the world. In the USA and China, industrial 3D printers are actively being developed for the construction of buildings and the production of aircraft parts. The Russian development may occupy a niche in mechanical engineering, energy and the space industry, where high accuracy is required when printing large-sized products.

Read materials on the topic:

Now on home

Start of deliveries scheduled for 2027

Over 51,000 new motorcycles were sold in Russia in 2025

The car will take at least a year to assemble

The application's audience has reached 20 million users

The model will be included in the list of cars for taxis, price - from 2.25 million rubles

All parking lots of the "Administrator of the Moscow Parking Space" are connected to the service

The cars will be supplied to the Moscow Transport Service Directorate

Deliveries to India may begin in 2028

The technology provides automated search for all types of defects in power units

The plane flew 500 km, accelerating to 425 km/h

The plant stated that the information about the termination of purchases for models 6 and 8 is not true

Scientists are using the "Ekran-M" installation