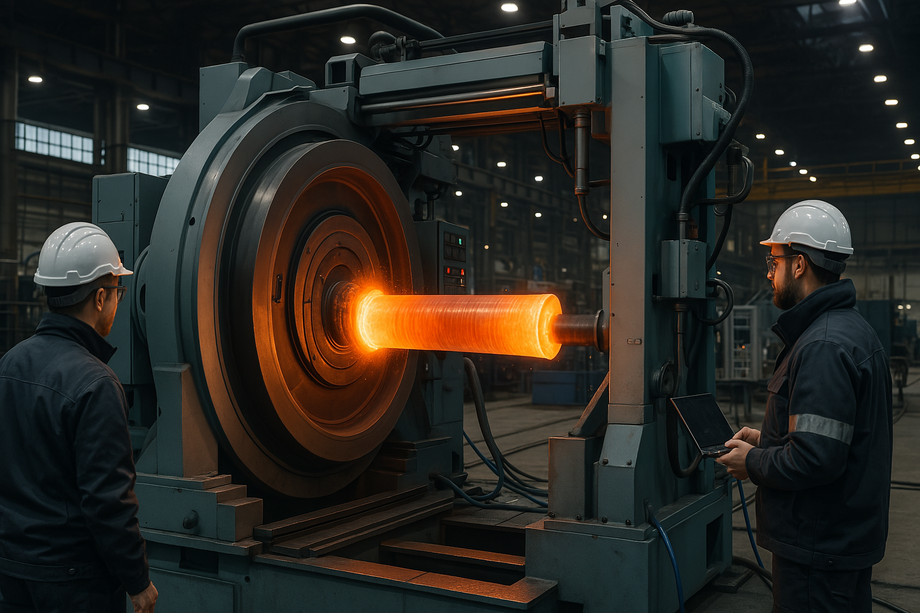

A new centrifugal casting unit for extra-large rolls has been put into operation at the Kushva Roll Plant (Sverdlovsk Region). The launch of the equipment, developed by local engineers, is timed to coincide with the 290th anniversary of the enterprise.

According to the Department of Information Policy of the region, the new machine will allow the production of rolls weighing up to 40 tons, which will significantly expand the plant's capabilities.

People have always been and remain at the heart of all decisions and global transformations. What you do at the enterprise, which Kushva and the entire Sverdlovsk region are proud of, makes it possible for the whole of Russia to develop. You are making a huge contribution to the development of the economy of not only the region, but the entire country.

The Kushva plant is one of the key metallurgical industries in the Urals, producing rolls with a full cycle: from metal smelting to finished products. More than 30% of the products are exported. The introduction of the new unit will reduce dependence on foreign supplies and increase the competitiveness of Russian industry.

Rolling rolls are the main parts of a rolling mill, which are used for processing metal (or other materials) under pressure. These are heavy metal cylinders (similar to rollers) between which hot or cold metal is passed to give it the desired shape.

Read more on the topic:

Nornickel Reduced Metal Production in the First Half of 2025

Tower Hydropower Plant in Itum-Kalinsky District of the Chechen Republic Put into Operation

Production of Furniture Using Metal Structures Launched in Bryansk with the Support of the IDF